Description

RGM is a multi functional digital controller designed for the proportional and PID control of the speed of high-speed, three-phase, asynchronous motors used in axial, radial and centrifugal fans for industrial HVAC/R applications. The control principle is base on balanced phase-cut control which permits smooth, accurate, optimized control, improves energy efficiency and reduces wear and tear on the components.

It supports proportional master, proportional slave and PID operating modes, and can be configured in both direct and reverse mode for maximum application flexibility. The PID control with auto-optimization allows the operating parameters to be maintained constantly, even under variable conditions.

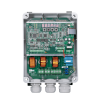

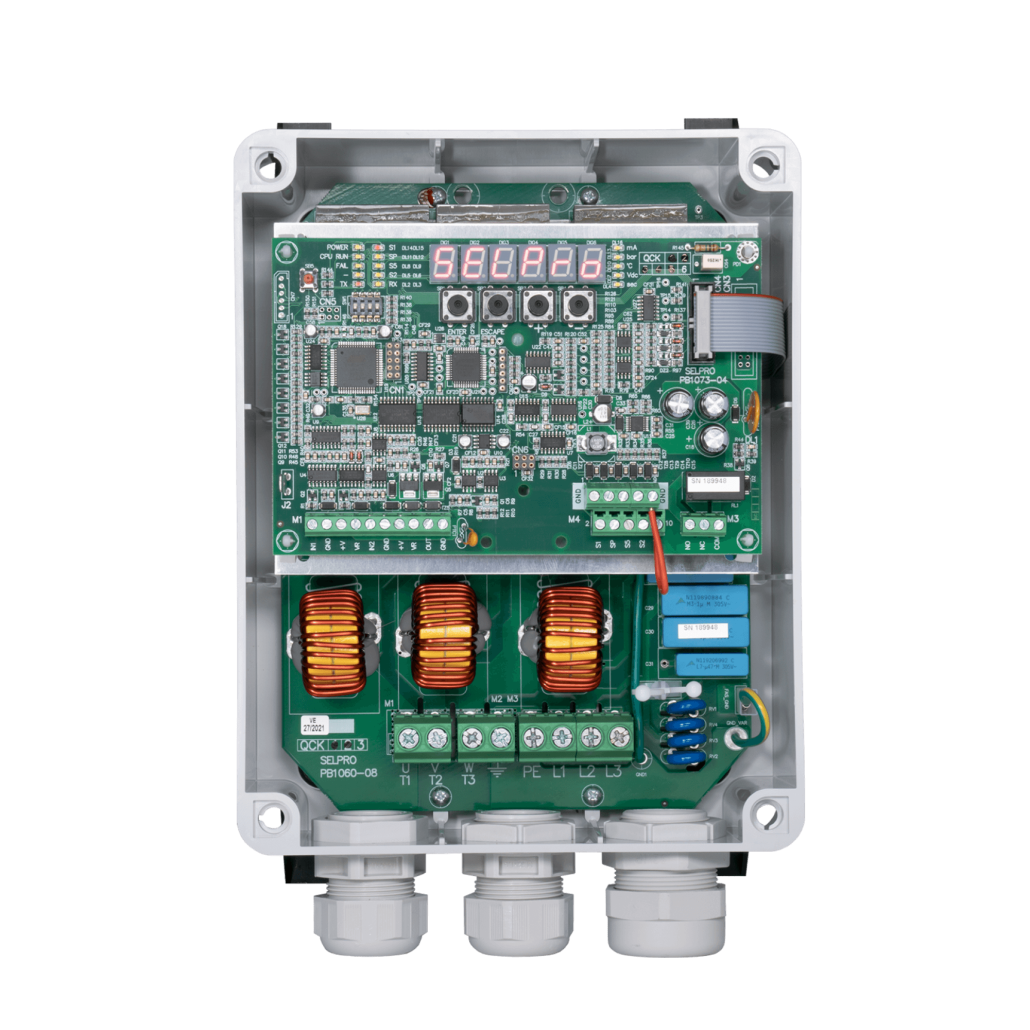

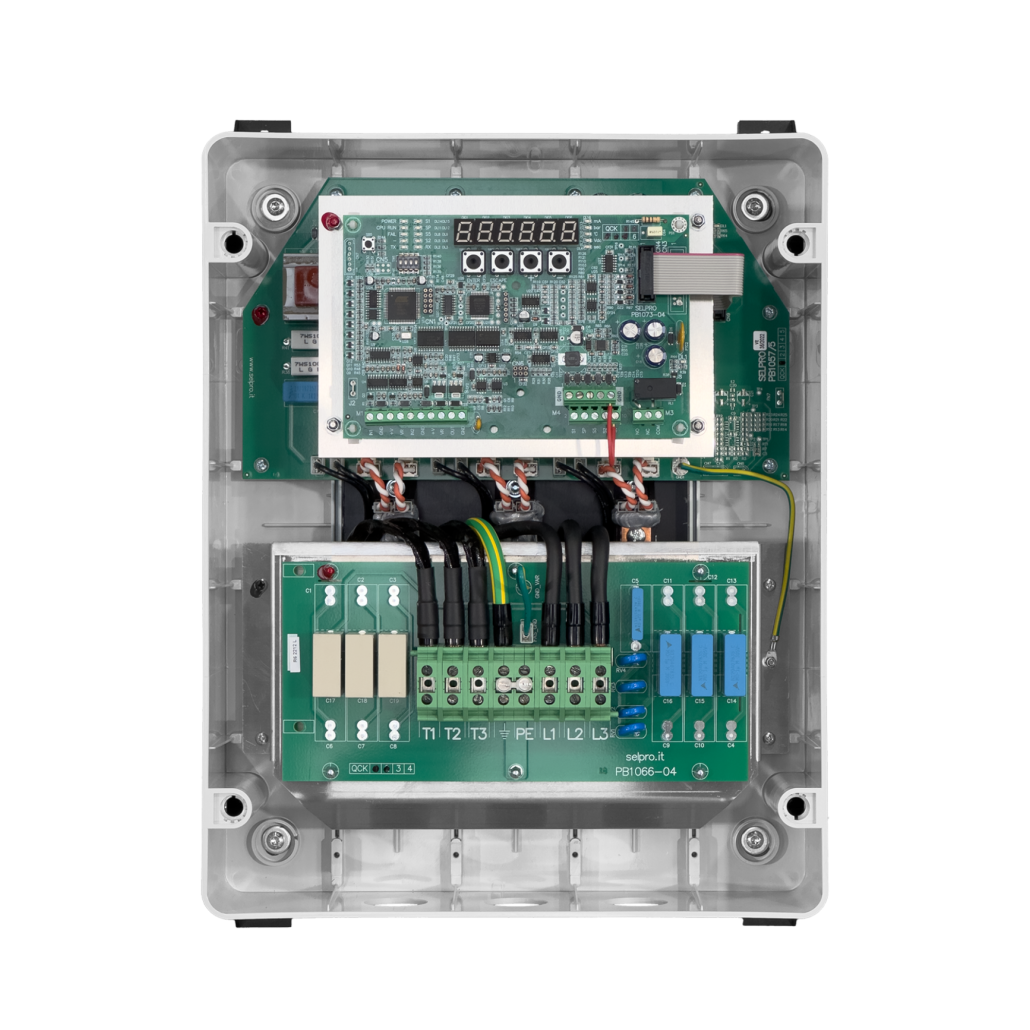

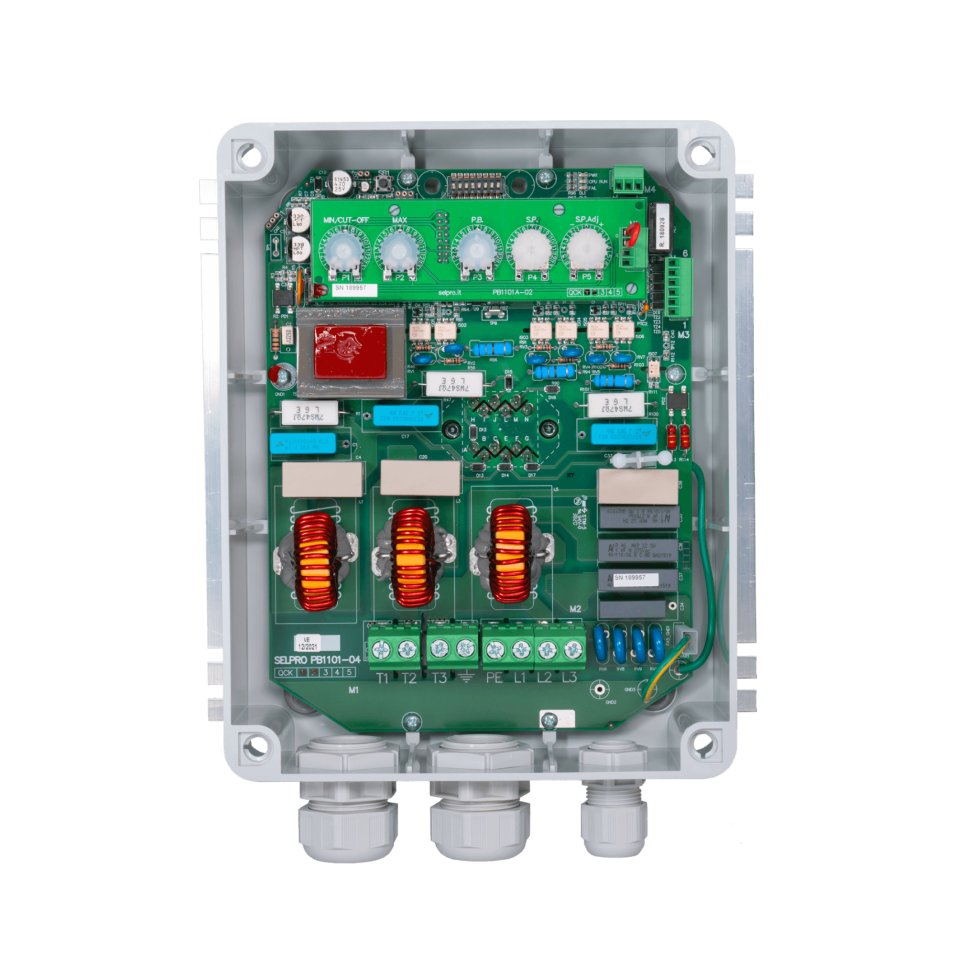

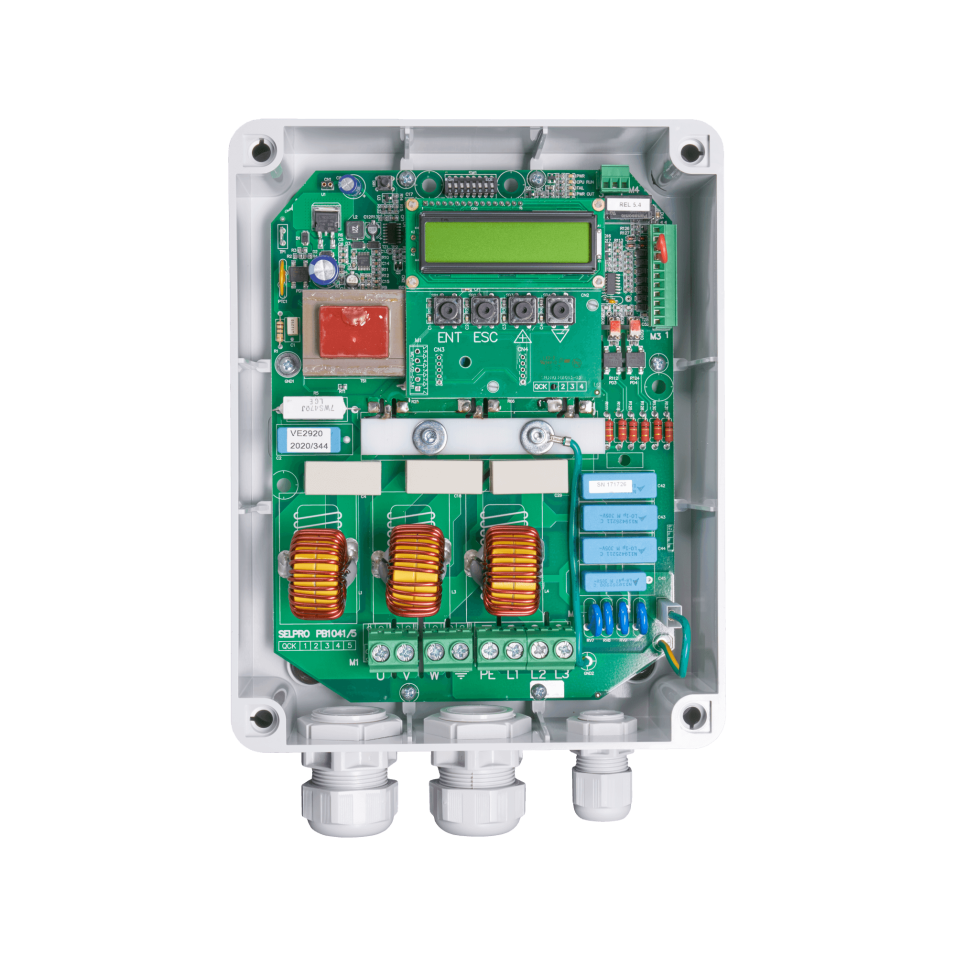

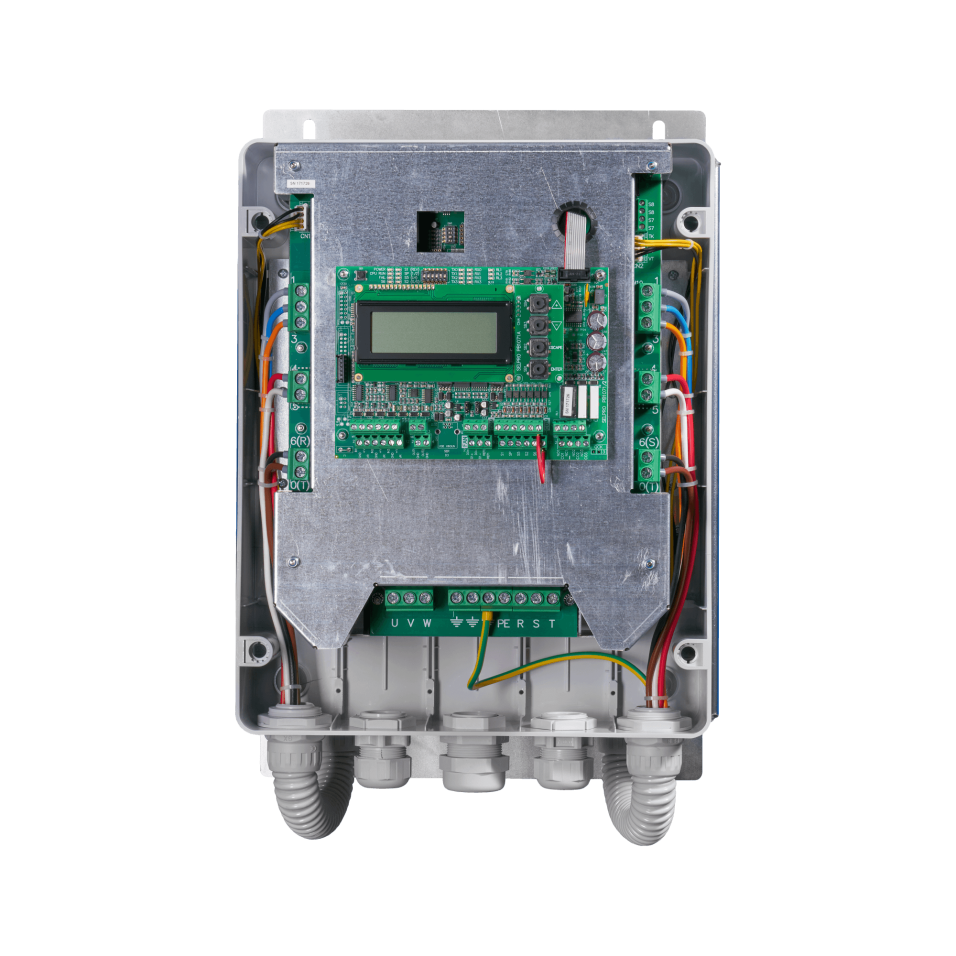

From the hardware standpoint, RGM uses bidirectional alternistors (TRIAC) for up to 28 A, chosen for their reliability in the management of medium-high currents. For higher currents, SCR (Silicon Controlled Rectifier) pairs are employed as they are ideal for high power applications thanks to their high conducting capacity.

A distinctive element of the RGM architecture is the ignition system of the SCRs/alternistors, carried out with pulse transformers designed to ensure ample pulse areas. Unlike optotriac-based solutions, this approach makes the command independent of the power voltage, improving stability and reliability, including where there are network fluctuations.

The controller has 2 analog inputs that are compatible with 0-20 mA, 4-20 mA, 0-10 Vdc and 0-5 Vdc signals and NTC probes (-10 / 90 °C). You can configure two independent sets of operating parameters to adapt the controller function to two separate types of working conditions (e.g. Summer-winter, day-night).

Auxiliary management is carried out by 5 on-off contacts that can be used for functions like remote Start/Stop, TK protection, nighttime limits, setpoint change and reverse mode.

RGM also contains a proportional 0-10 Vdc output to drive the slave devices and a relay to signal the alarms. Both can drive an adiabatic system, allowing for complete coordination between ventilation and evaporative cooling.

The controller was designed to be integrated with BMS systems through a Modbus RTU slave connection which can be turned on with an optional plug for the remote management of the parameters.

The protection against power surges and electromagnetic noise, along with the IP55 level of protection, makes RGM ideal for difficult environments as it can resist dust, humidity and vibrations.

Special functions like defrosting and antifreeze protection increase operating flexibility.

Inputs, outputs and connectivity

- Analog inputs: 2 inputs compatible with 0-20 mA, 4-20 mA, 0-10 Vdc, 0-5 Vdc and NTC (-10/90°C)

- Auxiliary on-off contacts: 5 programmable contacts (Start/Stop, TK, nighttime limit, setpoint change, reverse mode)

- Relay: 1 relay that can be configured for alarms or ON-OFF drive in adiabatic systems.

- Proportional output: 0-10 Vdc programmable for slave devices or adiabatic systems.

- Modbus RTU connection: slave (on optional plug)

Special features

- Adaptive, accurate control to ensure that the operating parameters remain within the defined setpoint, including with significant load variations.

- The device offers 2 control setpoints that can be set to the minimum or maximum limit with the option of configuring 2 parameter sets that can be customized to include nighttime limits, speed jumps, maximum and minimum speeds, acceleration ramps and other operating parameters to manage the various requirements on a flexible, adaptable basis.

1 0-10V outputs for one or more units to act as slaves to a main (Master) unit or to manage an adiabatic system with a set of specific parameters.

- 0-10 Vdc

- 1 ON/OFF output recommended to run on an adiabatic system

- Additional optional plug for isolated BMS Modbus RTU connection