Description

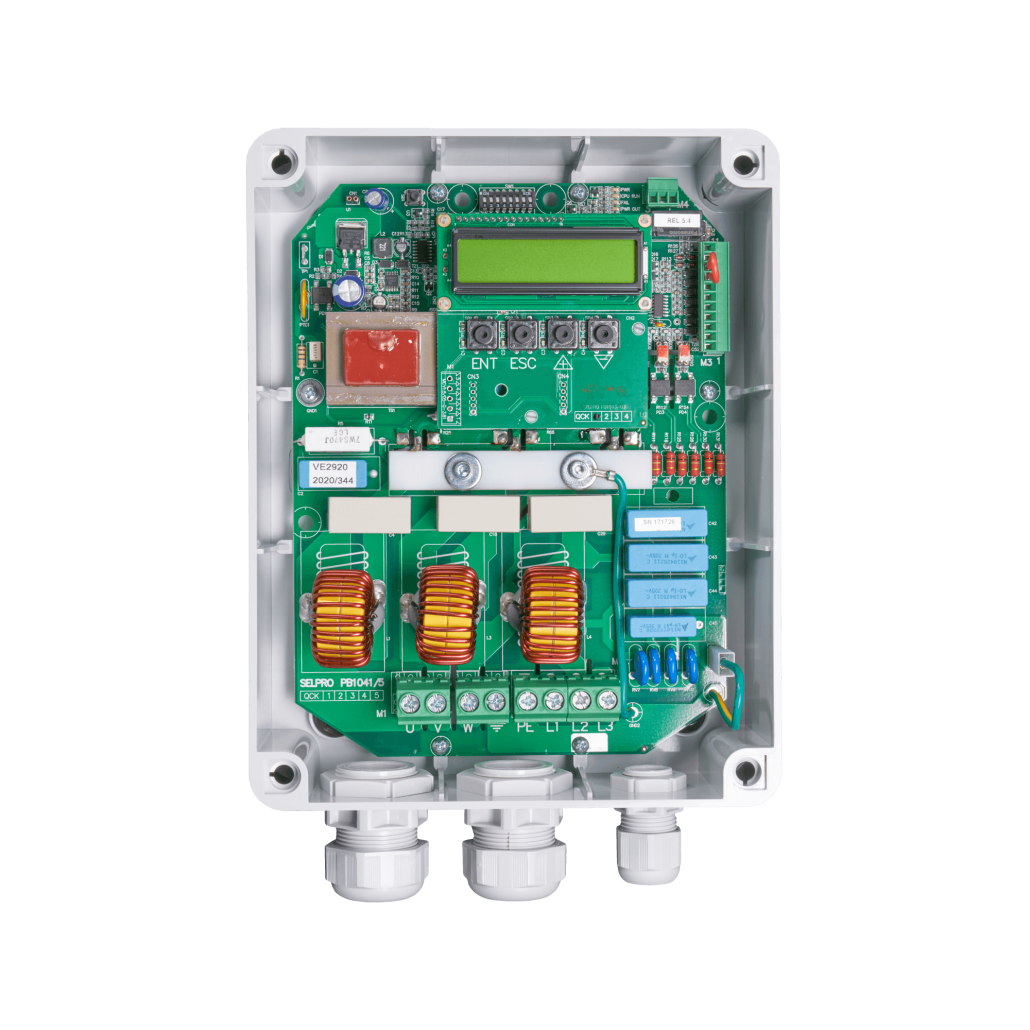

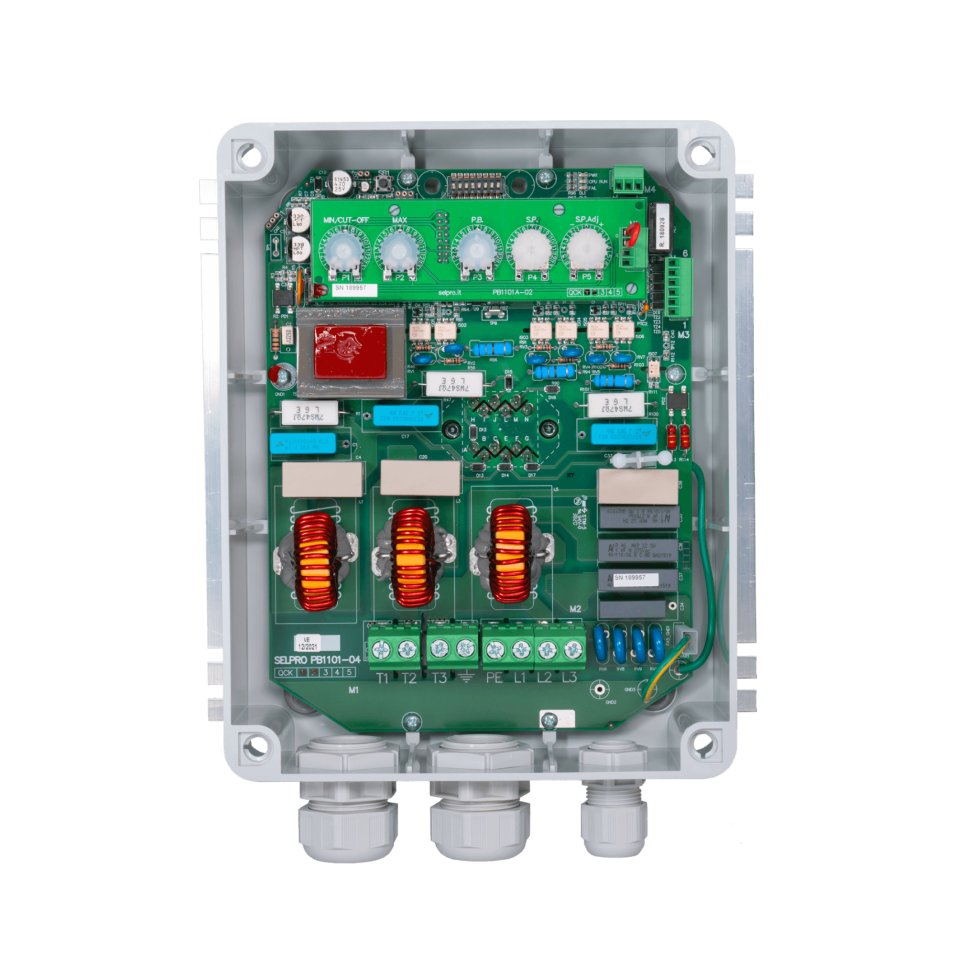

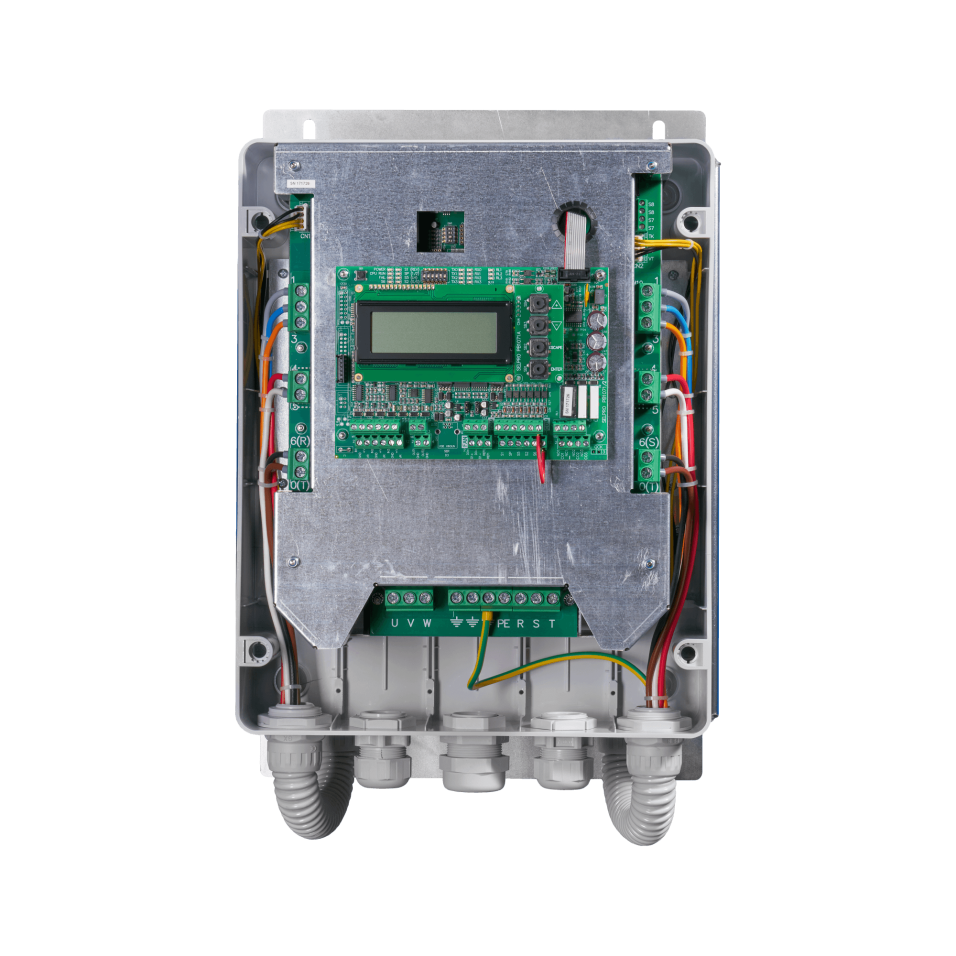

RDM is a multi functional digital controller designed to control the speed of high-speed, three-phase, asynchronous motors used on axial, radial or centrifugal fans in HVAC/R and industrial applications. The control principle is based on the phase-cut control balanced with the main supply principle which enables the accurate, dynamic control of ventilation, optimizing the energy efficiency and reducing electrical and mechanical wear and tear of the components.

The device is available in two software versions that can be chosen upon configuration: one with advanced PID control and one with a specific algorithm for Copeland Digital Scroll compressors. Both versions also support the proportional function mode and can operate as masters or slaves, providing up to 13 predefined configurations to fit any requirements of the system.

In the proportional PID version, RDM has two analog inputs compatible with 4-20 mA, 0-10 Vdc, 0-5 Vdc signals and NTC probes (–10 / 90 °C), as well as an independent input for the PWM signal. In the Digital Scroll version, there are two analog inputs, one compatible with 4-20 mA signals and one for 4-20 mA signals or an NTC probe (-10 / 90 °C). The type of signal read is determined by the chosen configuration. There are 3 configurations, each of which is divided in turn into two separate sets of parameters.

Both versions are equipped with two programmable on-off contacts. The proportional PID model can be configured for functions such as remote Start/Stop, TK protection, activation of nighttime limits or heat pumps. In the Digital Scroll version, the contacts are used for remote Start/Stop and TK protection readings only.

There is a programmable relay for alarms or other functions, while the analog 0-10 Vdc output enables the proportional command of slave devices or external actuators. The protection against power surges, overloading or heat anomalies ensures a high level of operating reliability, including in complex industrial areas. RDM is available in the IP55 version for external use or the IP20 version for installation in electric panels.

Its operating versatility, double software configuration and compatibility with Digital Scroll compressors all serve to make RDM a complete, high-performing option.

Inputs, outputs and connectivity

- Analog inputs (proportional PID version): 2 inputs compatible with 4-20 mA, 0-10 Vdc, 0-5 Vdc, NTC (–10 / 90 °C)

- PWM input (only PID proportional version): 1 independent input

- Analog inputs (Digital Scroll version): 1 4-20 mA input + 1 4-20 mA or NTC input (–10 / 90 °C)

- Auxiliary on-off contacts:

- PID proportional version: 2 programmable contacts (Start/Stop, TK, night limit, heat pump)

- Digital Scroll version: 2 contacts (Start/Stop, TK)

- Relay: 1 programmable relay for alarms or other functions

- Proportional output: 0-10 Vdc for slave devices

Special features

- Smooth, dynamic control to keep the system pressure or temperature stable, reducing energy consumption and improving the duration of the system.

- Adaptive, accurate control to ensure that the operating parameters remain within the defined setpoint, including with significant load variations.

1 0-10V output recommended for one or more Slave units to serve a main unit (Master)

- 0-10 Vdc