Digital control of fan systems with electronic switching motors has never been easier

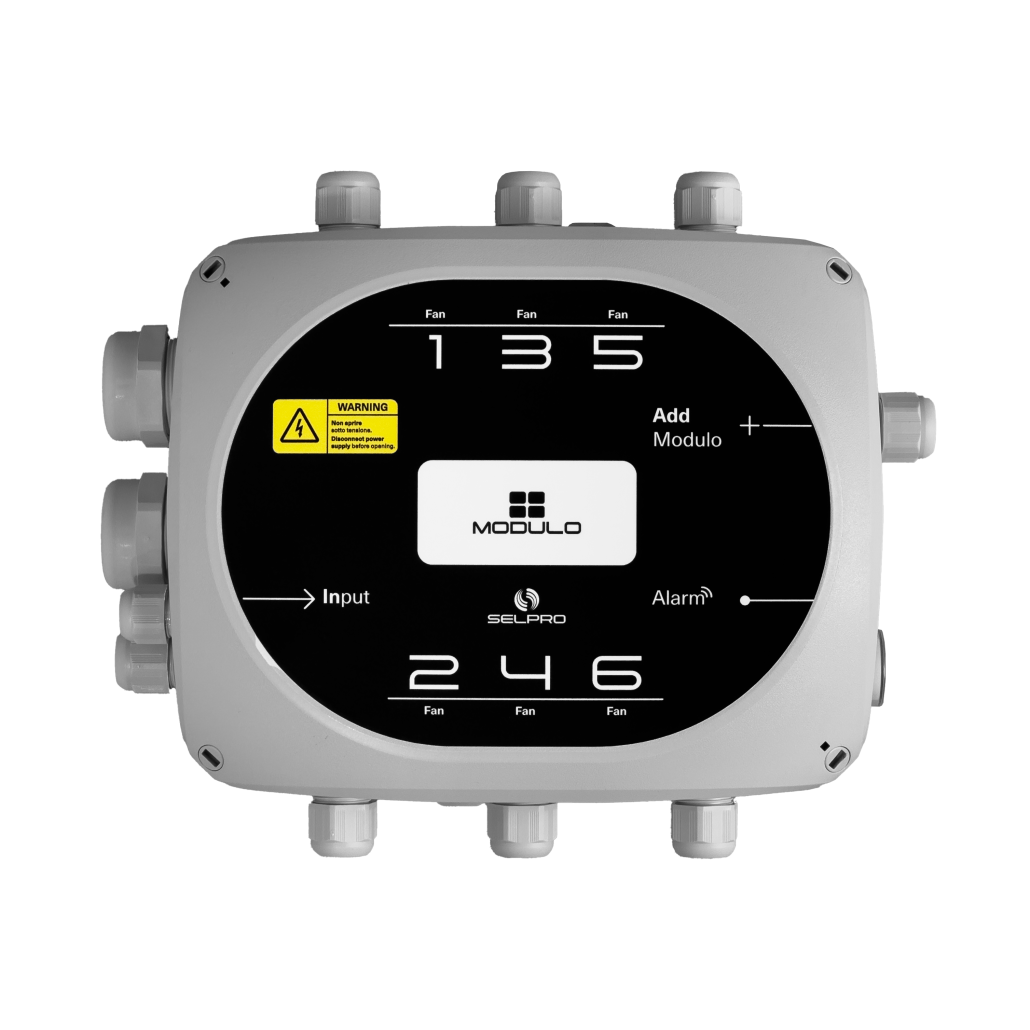

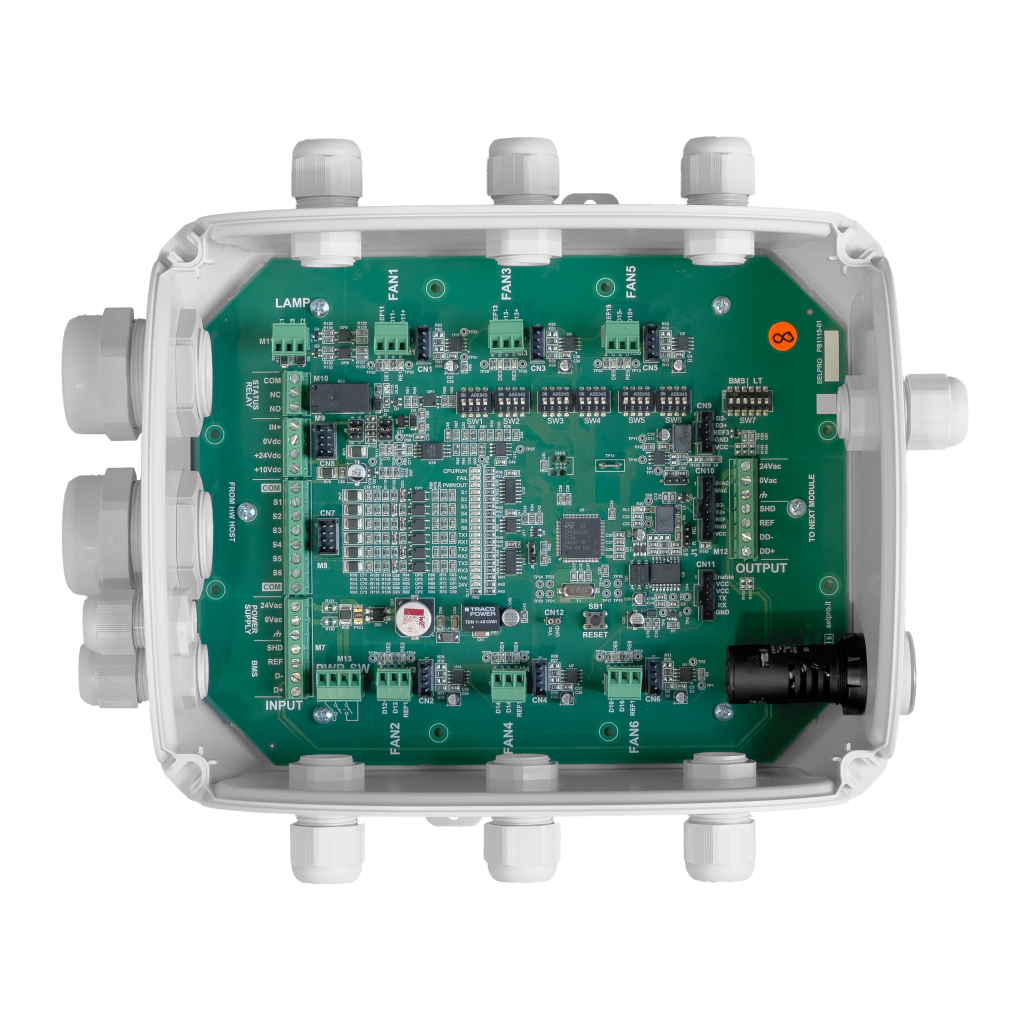

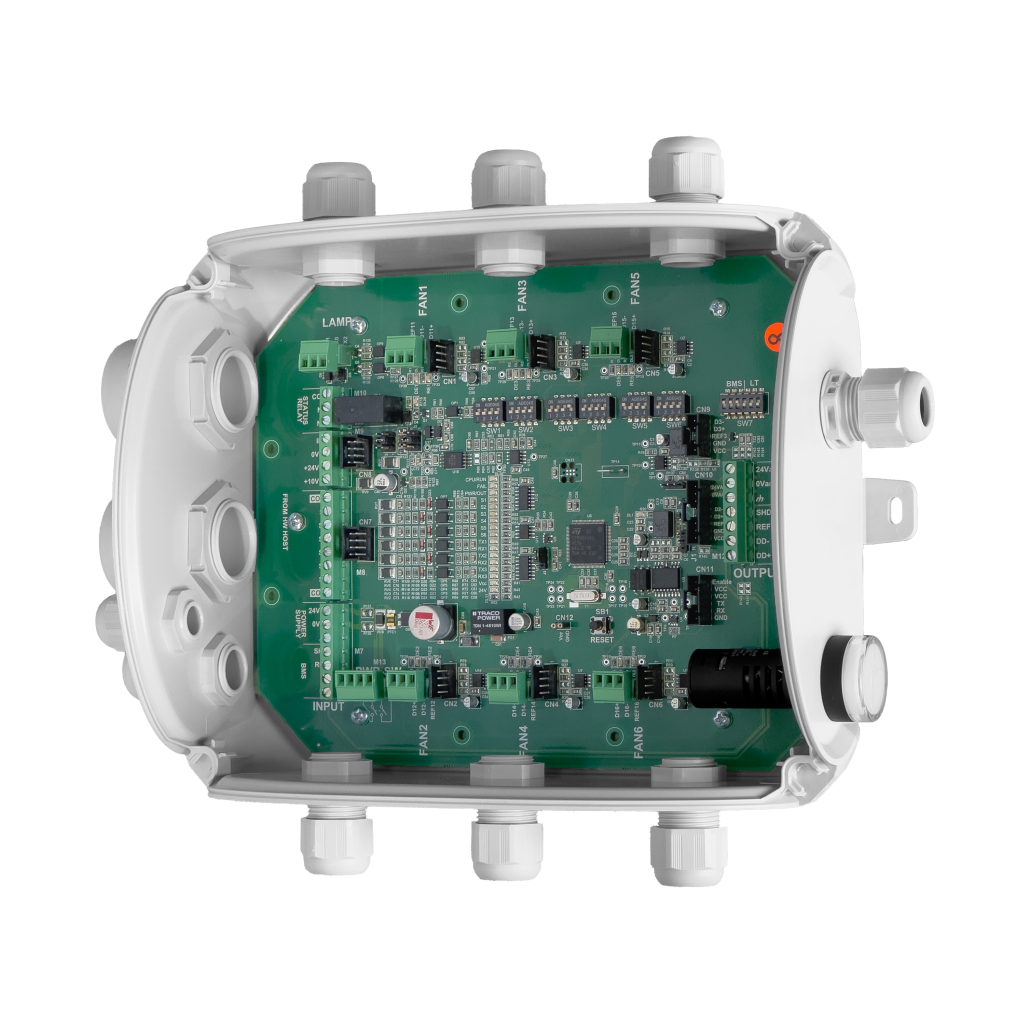

Modulo is an auxiliary device patented by Selpro that simplifies wiring and starts up the Modbus plug & play management for machines with electronic switching motors. Designed for both new installations and retrofits, Modulo is the intelligent bridge between the main control system and electronic switching motors as it automatically converts analog 0-10V and 4-20mA signals in the Modbus protocol selected.

Without replacing the main master controller, Modulo converts and digitizes the analog control of the system, also offering all the potential of the Modbus to the systems that use simple analog commands. It simplifies and makes the Modbus network wiring safer, significantly reducing installation and programming times, ensuring rapid, effective, future-proofed integration without having to change any hardware and/or incur steep redesign costs.

No programming or complex wiring

Automatic programming: Modulo identifies and assigns a unique address for up to 30 fans per circuit on an automatic basis, with no need for any complex operations, standardizing the operating parameters for all devices.

Easier wiring: Modulo gives immediate access to the advanced Modbus functions for intelligent ventilation systems, simplifying the wiring to only 3 cables (+ / - / Ref) per electronic switching motor. The automatic addressing and programming reduces installation times significantly, eliminating the risk of errors and facilitating integration with retrofitting projects on previously existing machines

Optimized control with maximum flexibility

Flexible configuration: Modulo allows electronic switching fans to be managed with standardized or customized speeds for each connected motor, optimizing airflow and energy efficiency in complex configurations like fan grids and fan walls.

Compatibility and modularity: with the Modbus protocols of the main manufacturers integrated. Modulo works on a stand-alone or expanded basis, and its modular architecture permits scalable configurations without having to reprogram them, ensuring simple, safe plug & play installation that can be adjusted to meet the specific requirements of the system.

Centralized and optimized data collection

Modulo makes it easier to monitor the fans thanks to its advanced, centralized data collection function. It automatically collects the information from each electronic switching fan, acquiring up to 20 main registers and 50 extended registers for each unit, gathering them into a single specific storage area which is updated in real time.

Modulo not only lightens the PLC’s load by minimizing fan polling and communication traffic, but also delivers data in a unified, standardized format, ready for Artificial Intelligence and Machine Learning algorithms. This is how the BMS or PLC can feed predictive models for energy efficiency, preventive maintenance or optimization of the setpoints, without requiring further calculating power or complex aggregation scripts. The operator can therefore obtain all the critical information from a single source, while the system is promptly ready for advanced analysis applications and intelligent automation.

Predictive maintenance and uninterrupted operation

Using the Modbus protocol Modulo monitors the status and work hours of each electronic switching fan in real time, promptly reporting faults or anomalies while triggering protection modes to prevent any critical conditions. This function reduces the need for urgent action and helps predictive maintenance, minimizing unplanned repair costs.

With the integrated active protections and Fail-Safe system, Modulo guarantees uninterrupted operation, even during technical malfunctions, maintaining ventilation and ensuring maximum reliability of the system.

The simplicity of 0-10V systems combined with Modbus power and versatility

Modulo combines the ease of use of 0-10V analog systems with the digital potential of the Modbus protocol for the intelligent control of electronic switching fans. Control through the 0-10V analog signal is appreciated for its simplicity: based on voltage changes to control fan speed.

However, this solution has significant limitations like vulnerability to electromagnetic disturbances, poor signal response in a linked network of over 10 meters and especially the inability to access data and/or monitor the operating status of the fan.

With the Modbus (RS-485) connection, Modulo can overcome all these limitations, ensuring bidirectional, , stable and reliable control, including over long distances. In addition to sending precise commands, Modulo gathers data in real time from each electronic switching fan, monitoring key parameters like speed, temperature, work times, energy consumption and alarm conditions, memorizing the malfunctions.

More accurate control and advanced system management without compromising the user-friendly simplicity of analog systems.

Advanced functions for optimized electronic switching fans

- Automatic reduction of the number of active fans

- Motor protection function if blocked due to ice or oxidation

- Detection, isolation and reporting of any malfunctioning electronic switching fans to ensure continuous operation of the fan cooling system.

- Starting up the automatic cleaning of the heat exchanger batteries thanks to the reverse rotation of the electronic switching motors.

- Limitation of RPMs to reduce air noise during the night in sensitive environments like hospitals, tourist or residential facilities.

- Active management of the motors to avoid the formation of condensation and/or moisture

- Continuous monitoring with reporting of anomalies and data collection for predictive maintenance.

- Speed management of the individual fans to optimize the RPMs in the fan grid or fan wall systems.

- Changing max RPM limits of connected fans to adjust performance of the system to meet the specific requirements of the application.

- Active monitoring to ensure stable connection without interference for every electronic switching motor.

- Use of passive cooling during nighttime hours or where the ambient temperature is low, reducing energy consumption.

- Fan cooling system motor testing

- Heat pump mode

- Control stop contact with motors at 0% RPM

- Control stand-by contact and motors at 100% RPM

- Activation of emergency RPM if the command signal is lost or the command cable or Modulo is damaged.

The most frequently asked

questions on Modulo

Modulo management software is available and was designed for the technical aspects relating to fan operation: therefore the speed of each motor, the power, the errors and the work times, along with the option to see all the registers that need to be managed, inputs and programmable holding registers.

This software lets you set the forms according to the type of machine or application and load them onto the entire group of interconnected units.

No, the fans do not have to be driven with Modulo. Every fan has a specific output so there is no need for complex configurations and the likelihood of communication errors is reduced. The addressing and programming are carried out automatically.

Yes, Modulo needs a controller to manage the ventilation system. Modulo works to support the controller, providing accurate, flexible control to each individual fan.

If there are communication problems, Modulo will isolate the problem to the individual fan without influencing the others in the system. This facilitates maintenance and improves the reliability of the entire system.

A Modulo can manage a cooling circuit since each circuit manages different signals. Therefore n Modulos to match the number of fans on each circuit (e.g. a machine with a maximum of 24 fans, so 12 motors per circuit, therefore 2 Modulos per circuit)