Description

ESK is a digital integrated control panel designed for the advanced control of single-phase, asynchronous motor speed that can function in master or slave mode, with proportional control through phase-cut control balanced with the main supply. It is particularly suitable for HVAC/R applications like dry coolers and condensers where it ensures accurate, reliable and modular control on the basis of the operating requirements of the system.

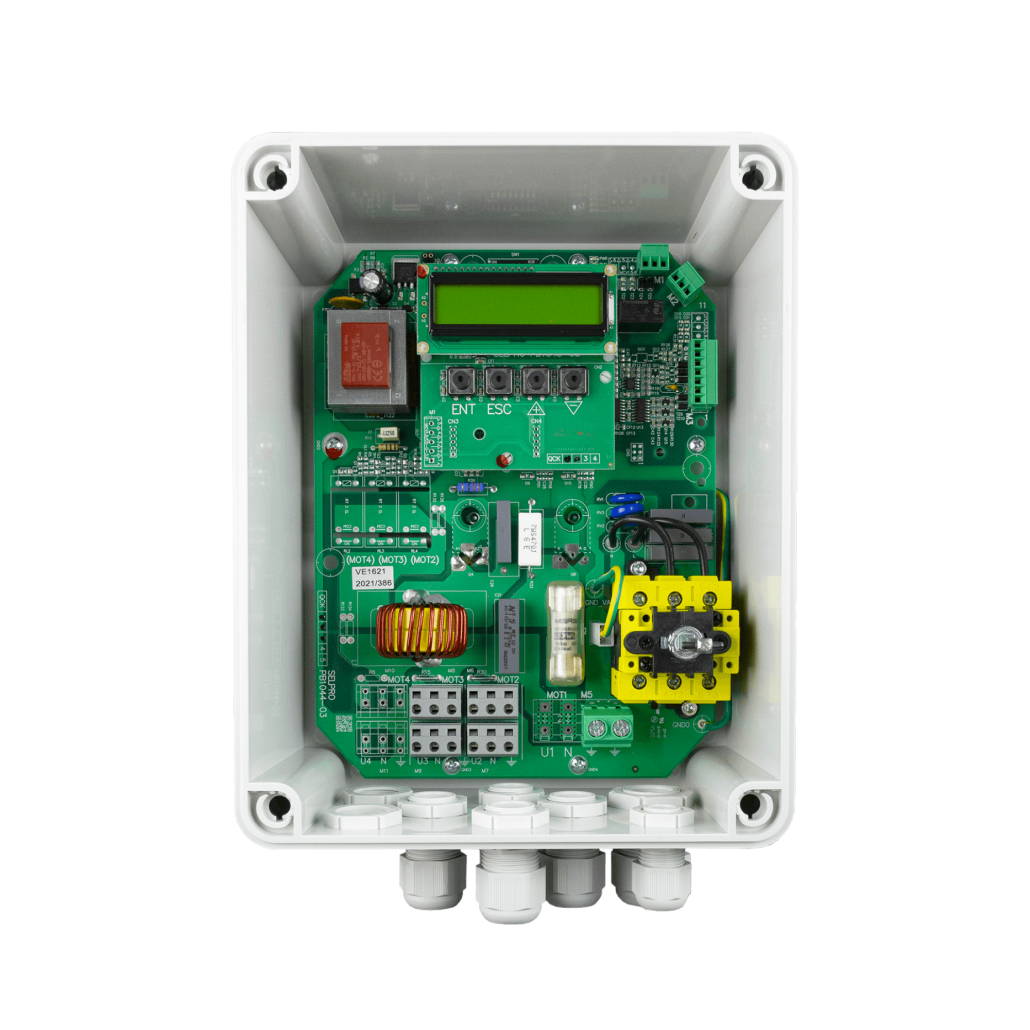

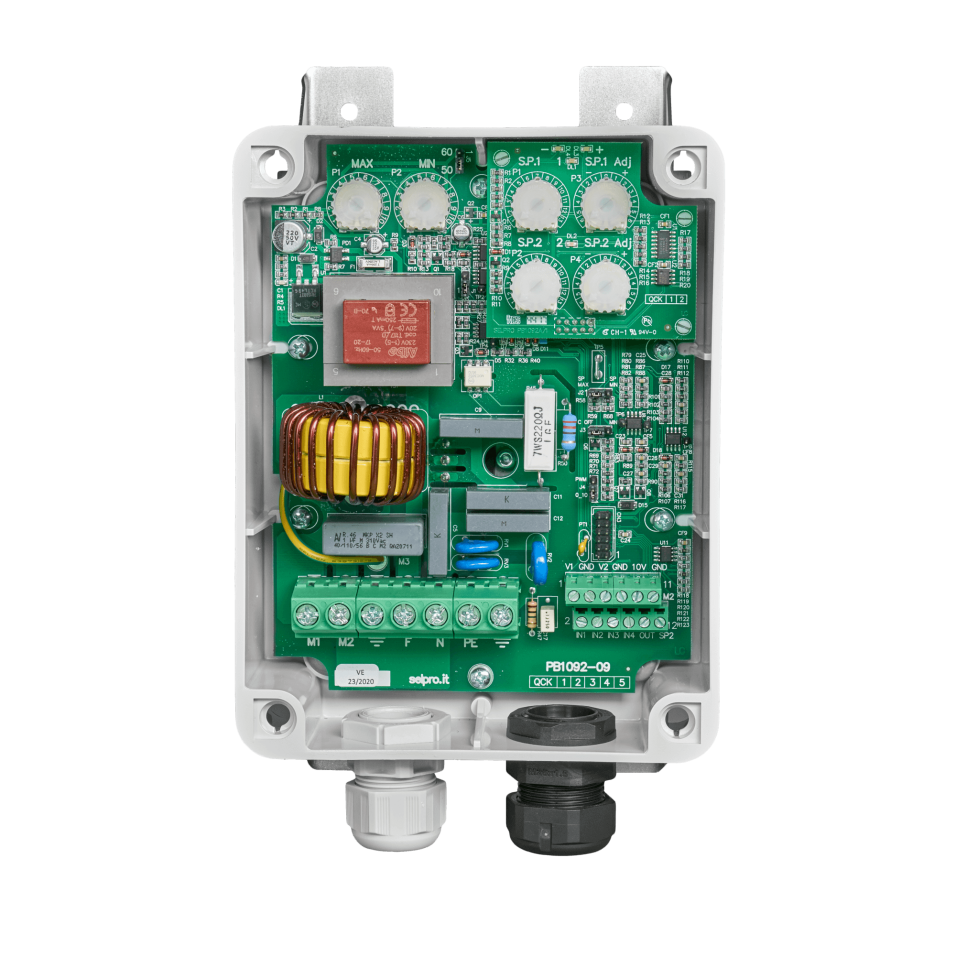

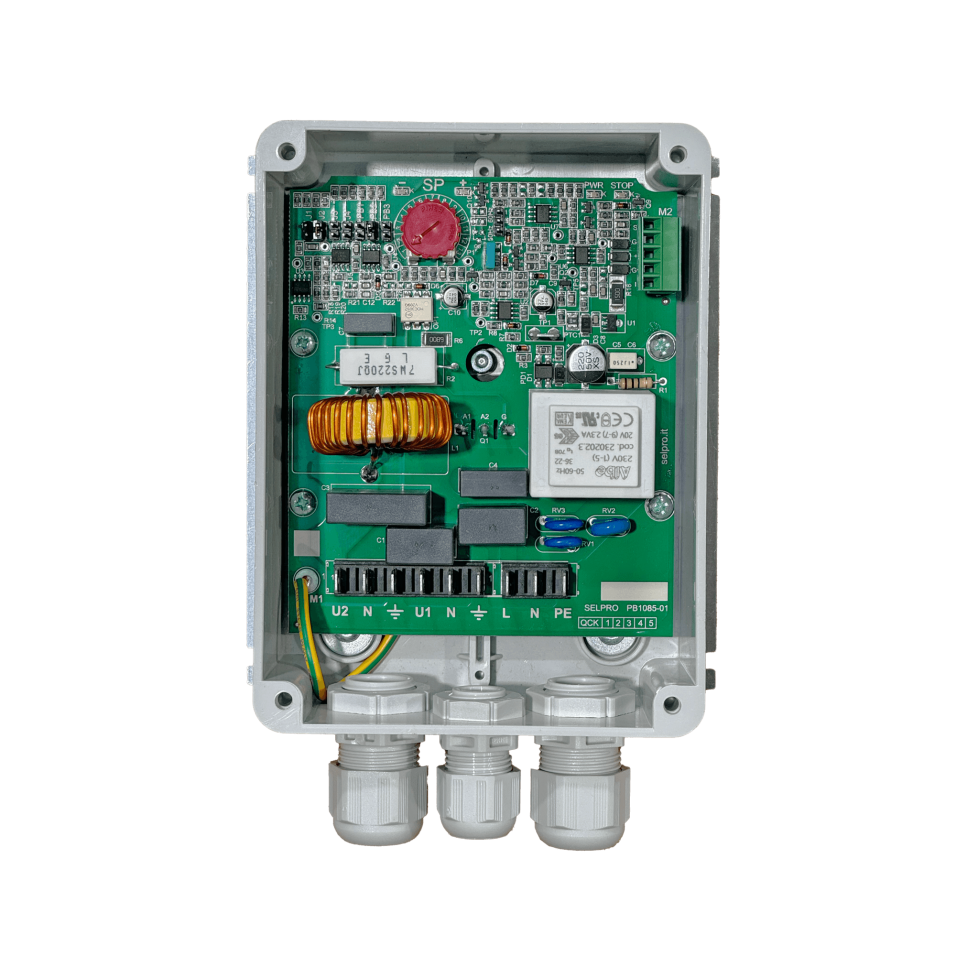

Based on compact, independent architecture, ESK includes a line switch and does not require external components for installation. The IP55 version is available for challenging environments or the IP00 version is available for installation in electric panels.

The system permits the management of 15 pre-set configurations that can be selected to quickly adjust to the various function modes. It is equipped with two analog inputs in master mode, compatible with pressure transducers 4-20 mA, 0.5-4.5 V or NTC probes (read range -10 °C / 90 °C). It accepts 0-10 V, 4-20 mA signals in slave mode and has an independent PWM input. There is also a third analog input (IN3), which can be customized on request, and it can be configured to accept 0-5 V, 0-10 V, 4-20 mA or NTC signals, providing further flexibility in advanced applications.

The controller controls two independent setpoints, with the option to configure two customized parameter sets: nighttime limits, minimum and maximum speeds, speed jumps and acceleration ramps. This enables extremely flexible control which can be adjusted to meet the requirements of various applications.

In order to support advanced modes, ESK is equipped with three programmable on-off contacts which can be used for functions like Start/Stop, setpoint change, reverse control or heat pump mode. Theauxiliary 0-10 V output allows slave devices to be driven directly, synchronizing a number of elements in the HVAC system.

The controller also includes a changeover relay with configurable functions that are useful for controlling the alarms or other auxiliary components. The protections on the command inputs and against power surges ensure high operating reliability and continuous operation.

It can be integrated into monitoring systems using the optional Modbus RTU plug which enables remote monitoring and interconnection with BMS or the system controller.

Inputs, outputs and connectivity

- Analog inputs (master): 2 inputs for transducers 4-20 mA, 0.5-4.5 V or NTC probes (-10°C / +90°C) 1 input for transducers 4-20 mA, 0.5-4.5 V or NTC probes for special functions

- Inputs (slave): 0-10 V, 4-20 mA, 1 PWM independent signal

- on-off auxiliary contacts: 3 programmable contacts (Start/Stop, setpoint change, reverse function)

- Auxiliary outputs: 1 0-10 V output to drive slave devices

- Relay: 1 configurable changeover relay

- Modbus RTU connection: available through optional plug

Special features

- Two different control setpoints and two sets of associated parameters are available. You can select one of the setpoints and related parameter set using an On/Off input.

1 0-10V output to serve one main unit (Master) by one or more

- 0-10 Vdc Slave units

- BMS Modbus RTU support with plug (optional) for easy integration with monitoring systems and advanced remote monitoring.