Description

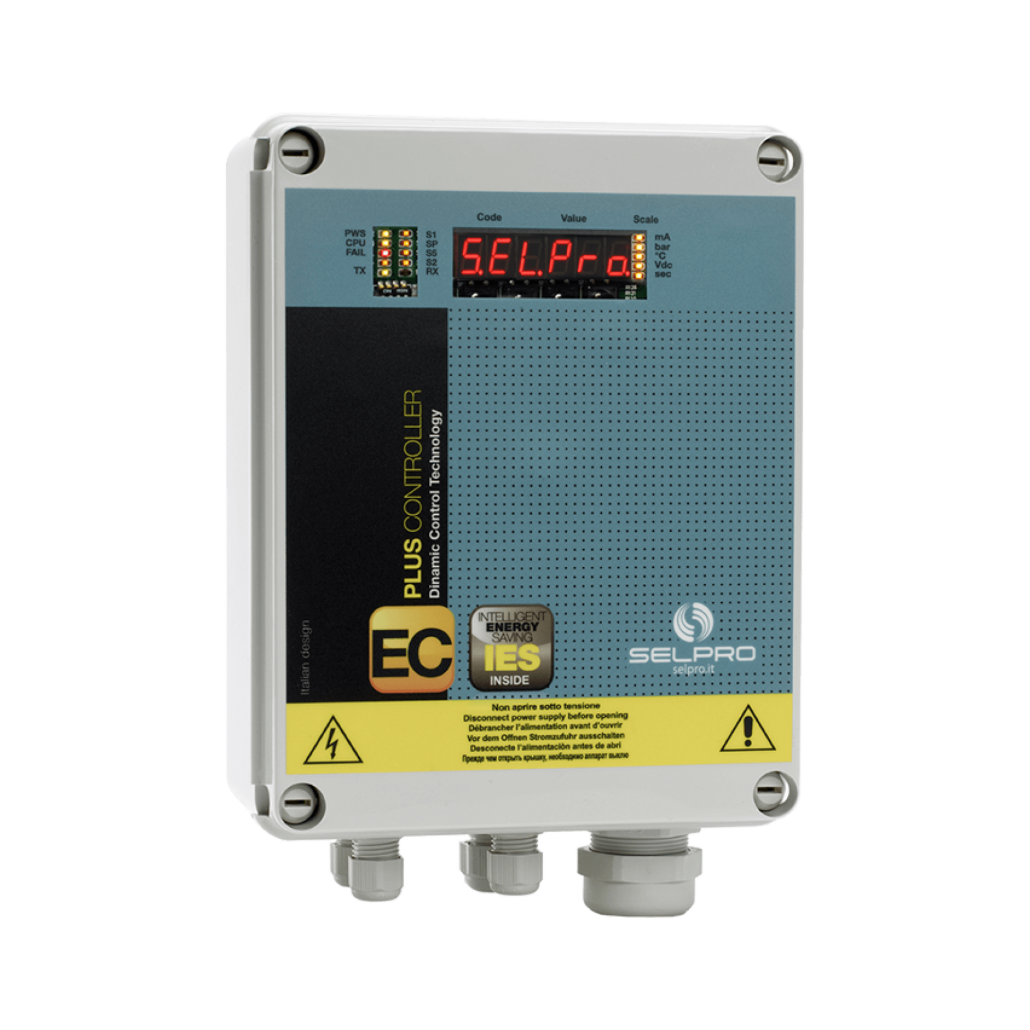

ECP is a multi functional, digital controller designed to provide accurate, dynamic control of electronic switching motors in HVAC/R systems like dry coolers, remote condensers and fan-grids. Based on the 0-10 Vdc command signal, it permits smooth, continuous, optimized proportionate control, helping to save energy and reduce wear and tear on the components.

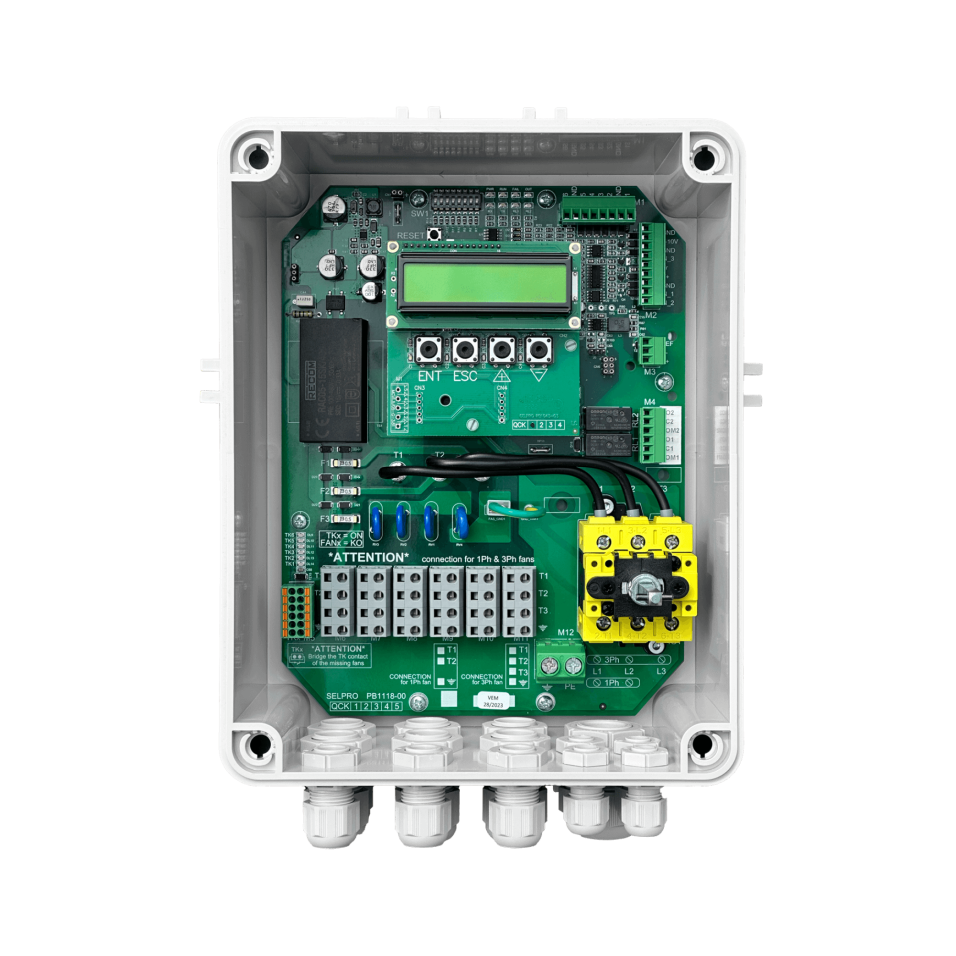

Designed to operate in master or slave mode, ECP supports direct or reverse proportional control and PID control, ensuring the stability of the operating parameters, including in variable conditions. It is compatible with single-phase and three-phase electronic switching motors, including the ebm-papst and Ziehl-Abegg certified models.

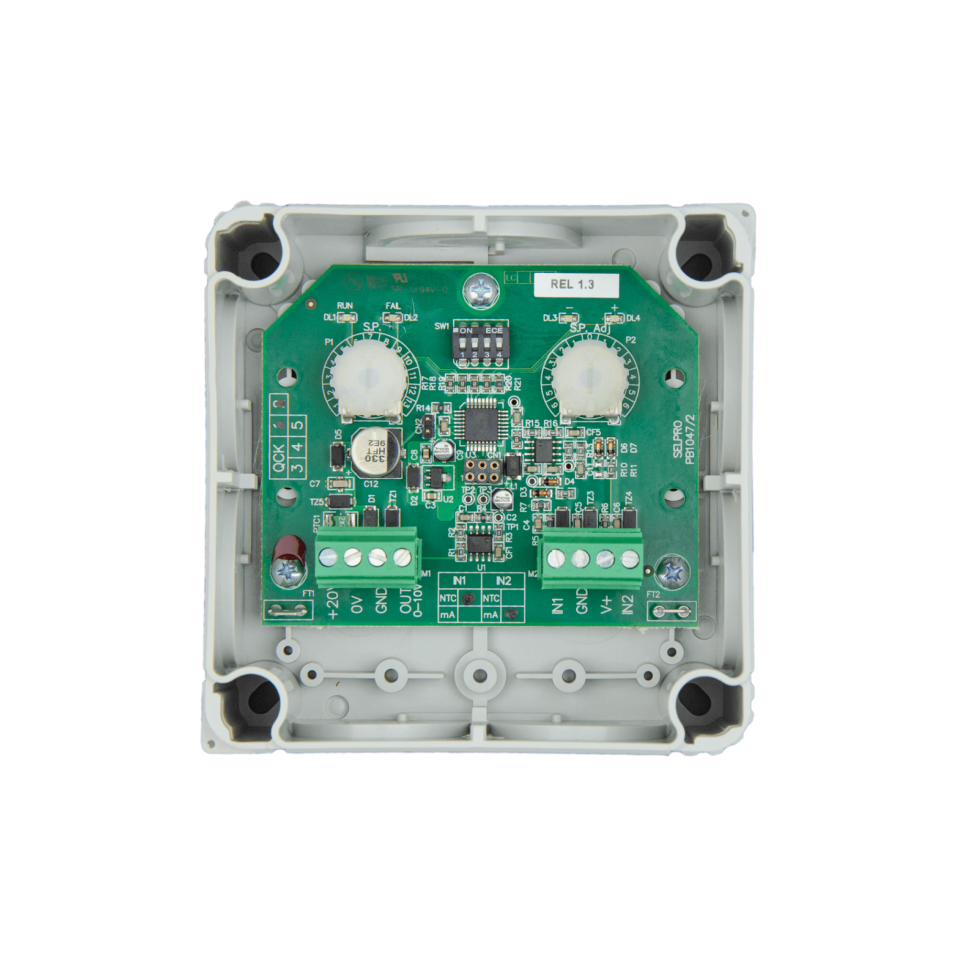

The single 0-10 Vdc command output, protected against short-circuiting, allows up to 30 electronic switching motors to be driven with impedance of ≥100 kΩ, ensuring efficient operation even in complex systems. The device has two analog inputs which can be configured as 4-20 mA, 0-10 Vdc, 0-5 Vdc or NTC 10 kΩ @ 25 °C, with automatic selection of the highest value between the two signals.

Operational flexibility and customization:

the controller has 2 analog inputs that are compatible with 0-20 mA, 4-20 mA, 0-10 Vdc and 0-5 Vdc signals and NTC (-10/90°C) probes, with automatic selection of the highest value. You can configure two independent sets of operating parameters to adapt the controller function to two different working conditions (e.g. summer-winter, day-night).

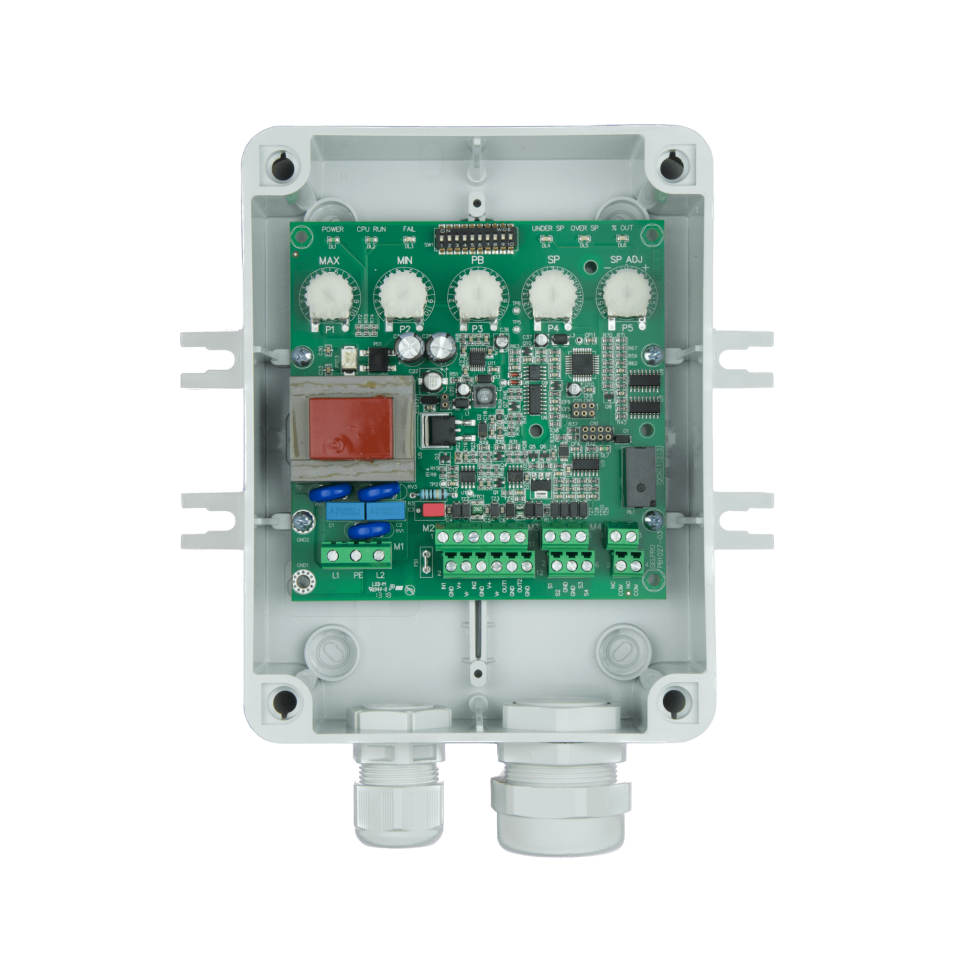

Auxiliary operation is carried out by 5 on-off contacts that can be used for functions like remote Start/Stop, TK protection, nighttime limits, setpoint change and reverse mode.

The alarm relay on board can be programmed and may be set up to turn on or off an adiabatic system to provide complete coordination between ventilation and evaporative cooling.

Diagnostics and reliability:

the Modbus RTU connectivity (through an optional plug) enables integration with BMS systems and remote monitoring of the operating parameters.

Available in the DIN-rail version or for outside use with IP55 protection.

Inputs, outputs and connectivity

- 2 configurable analog inputs that are compatible with 4-20mA, 0.5-4.5V transducers and NTC probes (-10/90°C); in slave mode, with acceptance also of 0-10V and 0-20mA.

- Modbus RTU interface optional for connection with remote BMS systems.

- 1 0-10Vdc output for slave device commands or management of electronic switching fan units.

- 5 auxiliary on/off contacts that can be programmed for advanced operating functions.

- 1 relay that can be configured to control the alarms or to manage adiabatic systems.

Special features

- Adaptive, accurate control to ensure that the operating parameters remain within the defined setpoint, including with significant load variations.

- The device offers 2 control setpoints that can be set to the minimum or maximum limit with the option of configuring 2 parameter sets that can be customized to include nighttime limits, speed jumps, maximum and minimum speeds, acceleration ramps and other operating parameters to manage the various requirements on a flexible, adaptable basis.

- 1 ON/OFF output recommended to run on an adiabatic system

- Additional optional plug for isolated BMS Modbus RTU connection