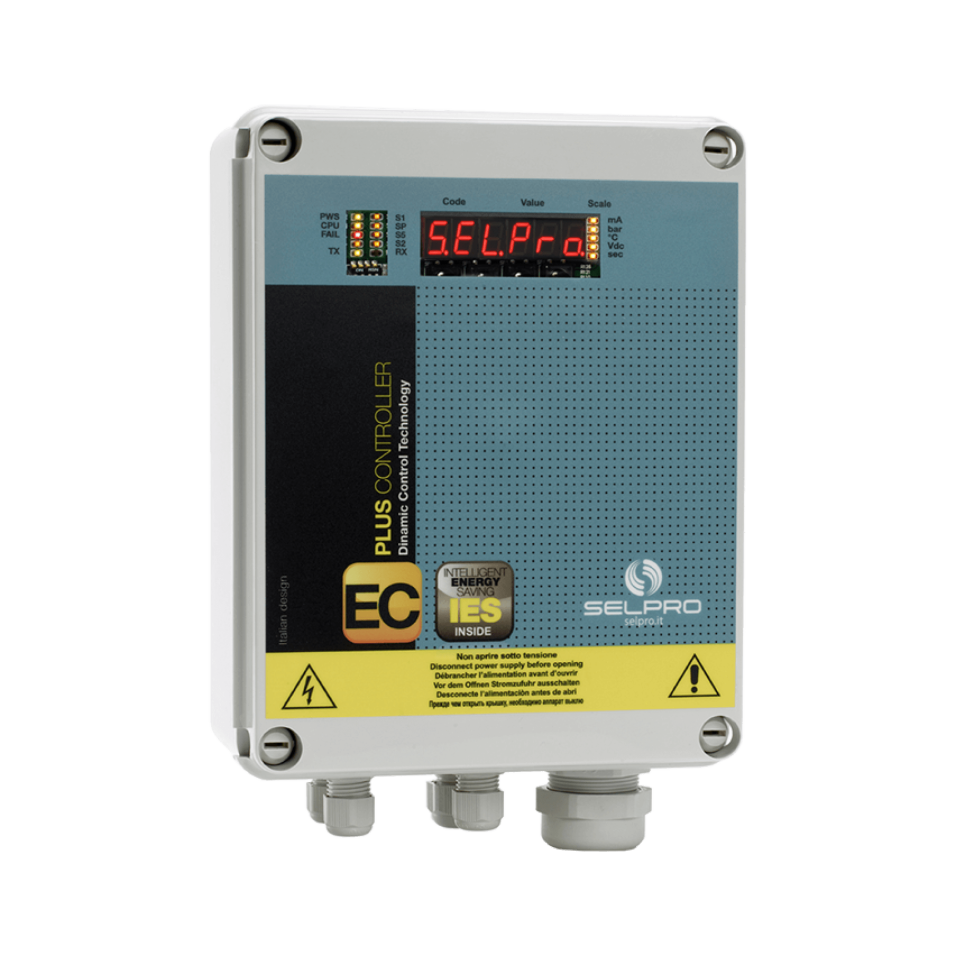

Advanced control for electronic switching motors and Adiabatic Systems

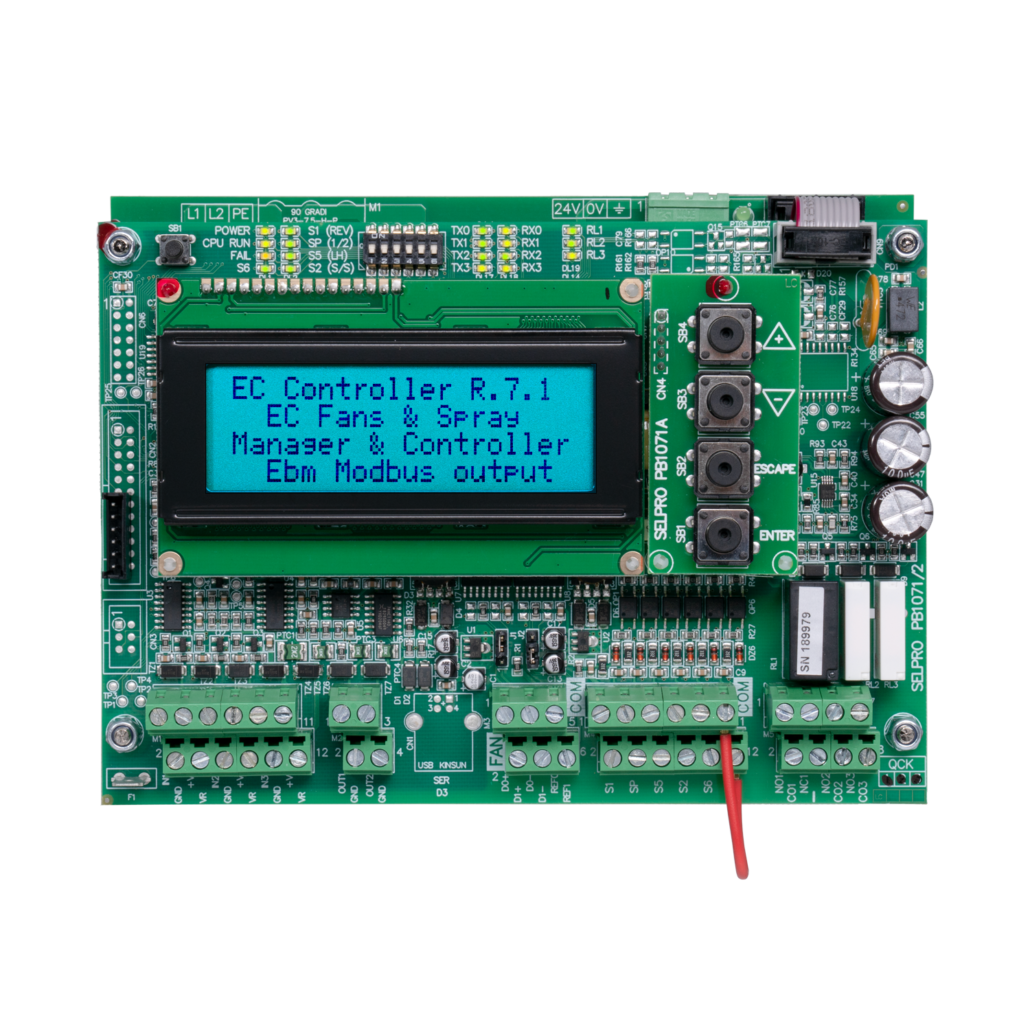

EC-Manager is an advanced electronic controller, designed for the accurate, dynamic control of electronic switching motors in HVAC/R applications like dry coolers, condensers, Fan-Grids and air purifying units. Based on Modbus RTU communication, it guarantees continuous, standardized control, intelligent monitoring and complete integration with BMS systems.

It has been approved by the main manufacturers of electronic switching motors including ebm-papst and Ziehl-Abegg, ensuring full compatibility and interoperability. The communication protocols are always available and can be easily turned on by switch, making installation, turning on and assistance much easier.

It manages up to 32 electronic switching fans on 247 addresses, with direct speed control with Modbus and/or a 0-10Vdc analog command. Quiet, progressive, optimized control helps save energy and reduce noise.

Operational flexibility and customization:

its operating modes include Master PID, proportional Master and proportional Slave in addition to 13 predefined configurations for rapid adaptation to the various applications. You can control 2 independent setpoints and 2 customizable parameter sets to define the limits, thresholds and dynamic behavior as specifically required.

Intelligent control of the adiabatic systems:

ECM is set up for the advanced control of wet & dry coolers, turning on the evaporative cooling according to the temperature, humidity or programmed times, ensuring efficient, coordinated function between ventilation and the water system.

Advanced diagnostics and reliability:

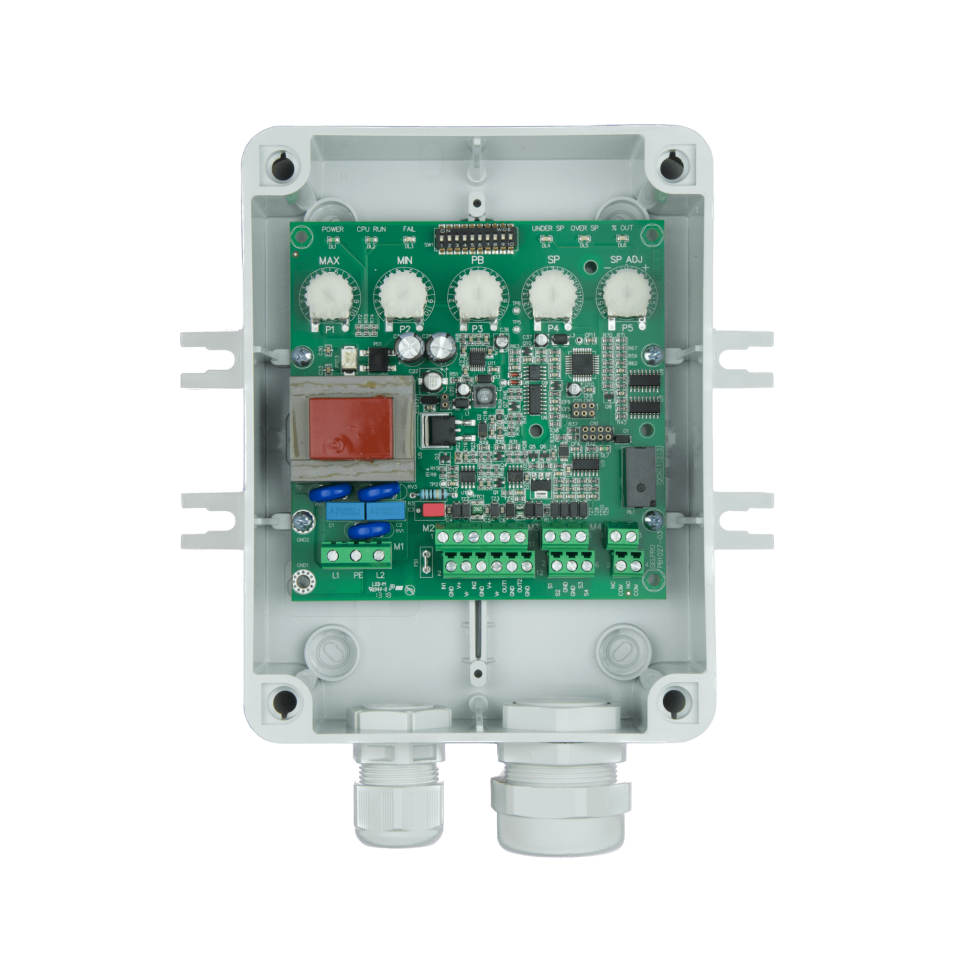

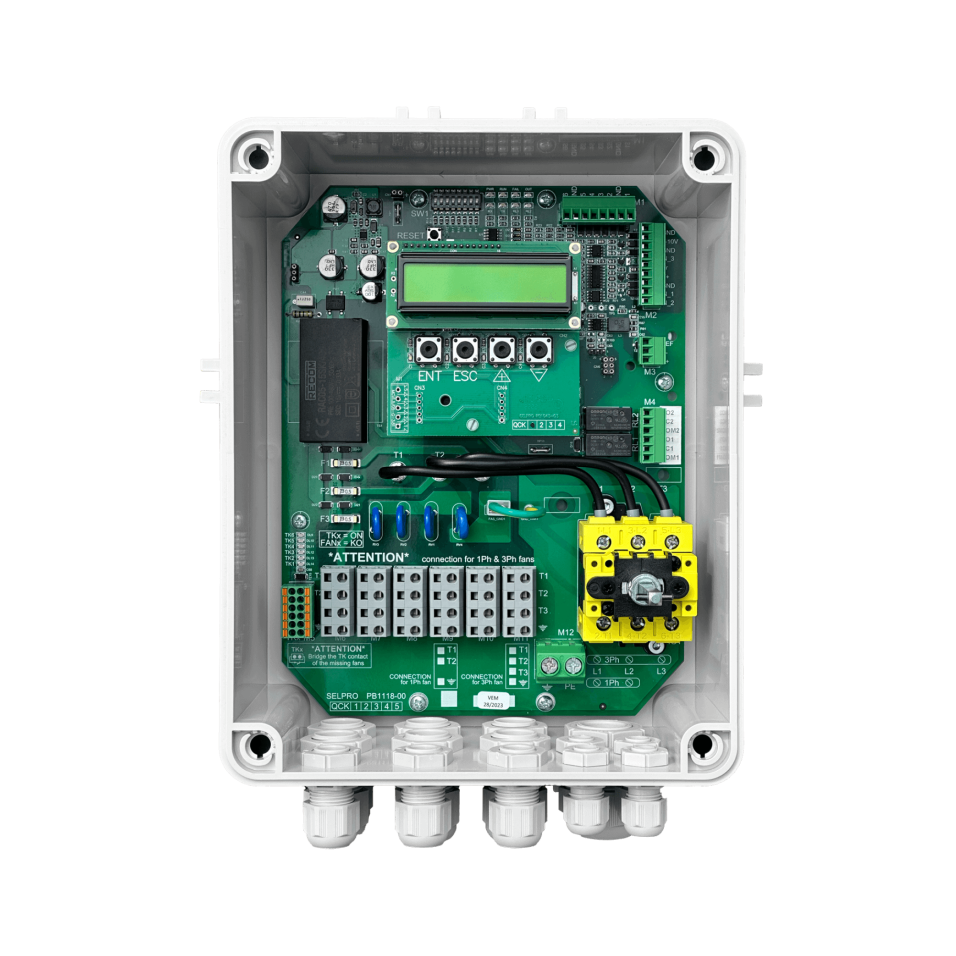

it has an event register with an internal real time clock (RTC) to track errors, statuses and operating transitions. Available in a DIN-rail version or for the outside with IP55 protection, it was designed to operate in challenging environments thanks to protection against power surges, overloading or EMC noise.

EC-Manager is the complete solution for the efficient, reliable and intelligent control of electronic switching motors and advanced cooling systems.

Inputs, outputs and connectivity

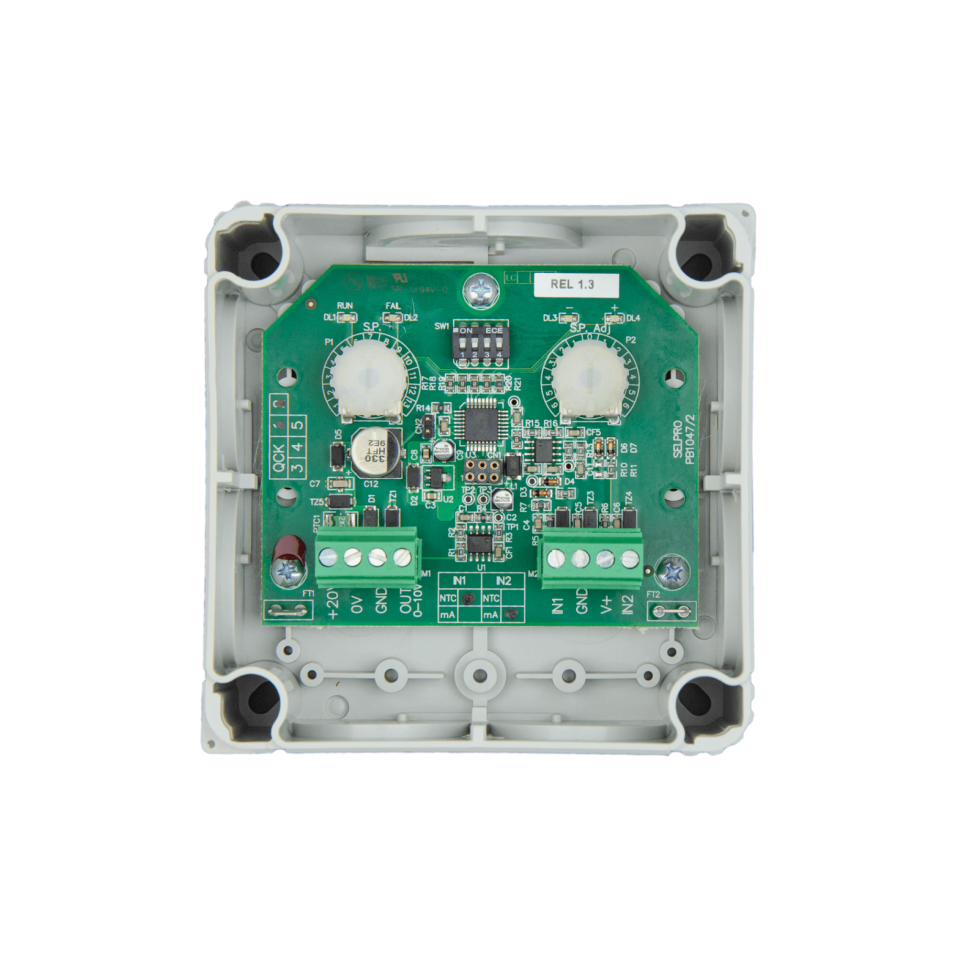

- 2 configurable analog inputs compatible with 4-20mA and 0.5-4.5V transducers and NTC probes (-10°/90°C); in slave mode, it also accepts 0-10V and 0-20mA.

- Analog input for special reading functions and/or remote control.

- Isolated Modbus RTU interface, and for connection with the fans in the Modbus network.

- Isolated Modbus RTU interface, and for connection with remote Master/BMS.

- 20-10V outputs that can be programmed for slave devices or adiabatic systems.

- 6 auxiliary ON/OFF contacts programmed for the various operating functions.

- 3 relays that can be configured to control the Alarms, the Warnings and the adiabatic system.

Special features

- Starts up periodic battery washing cycles to maintain heat exchanger performance.

- It avoids possible fluctuations in the system, gradually controlling the activation or deactivation of the individual fans to optimize ventilating power and adjust it to ensure it maintains the minimum values needed.

- Switches on the motors on a timed basis to eliminate humidity, introducing alternating rotations to prevent the blades from locking or ice forming.

- Reduces the maximum fan speed at programmed times to reduce nighttime noise and consumption.

- Automatic selection of the working parameter set for control based on outside temperatures detected.

- Carries out an automatic cleaning cycle on a programmed basis to improve efficiency and reduce maintenance.

- Dynamically adjusts the Setpoint according to the temperature changes detected.

- Permits remote control of the Setpoint through external analog signals (0-10V or 4-20mA)

- Guarantees the safety function if the main signal is lost, using emergency parameters.

- This function is always active to prevent damage to the components.