Descrizione

RGM è un regolatore digitale multifunzione progettato per il controllo proporzionale e PID della velocità di motori asincroni trifase ad alto scorrimento, utilizzati in ventilatori assiali, radiali e centrifughi per applicazioni HVAC/R industriali. Il principio di regolazione si basa sulla parzializzazione trifase a taglio di fase bilanciata, che consente un controllo fluido, preciso e ottimizzato, migliorando l’efficienza energetica e riducendo l’usura dei componenti.

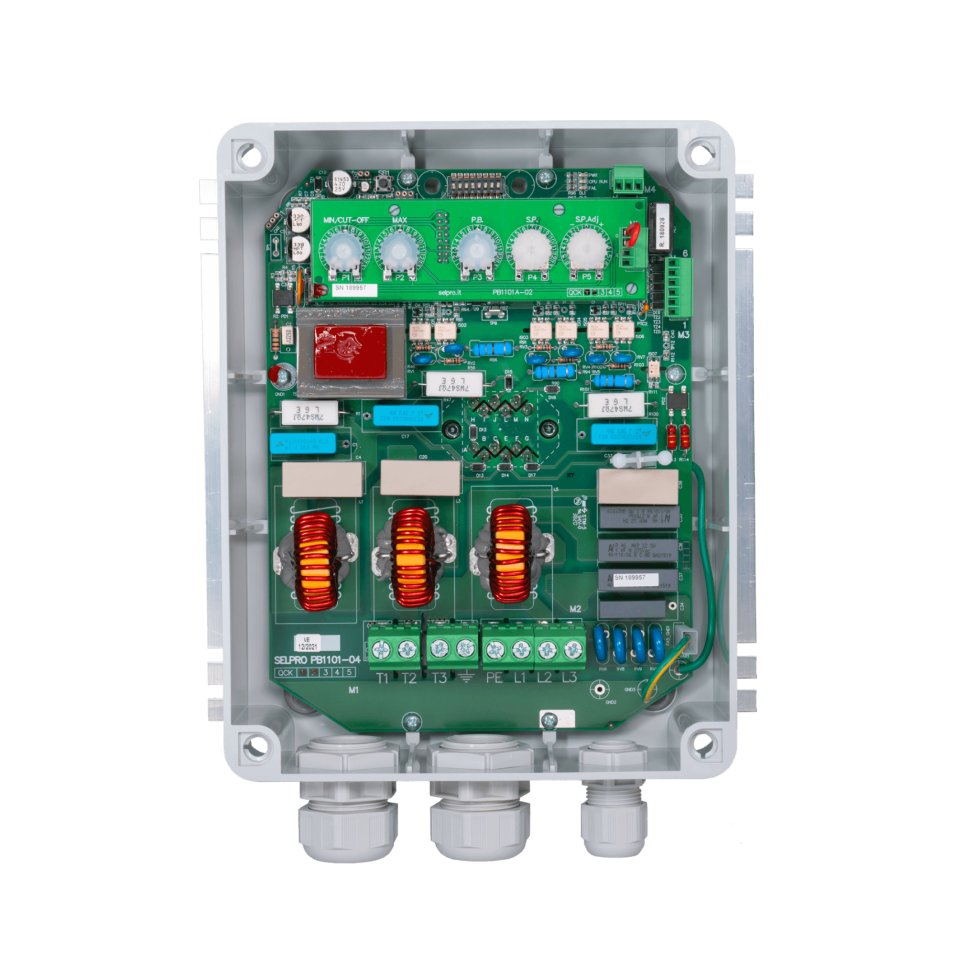

Supporta modalità operative master proporzionale, slave proporzionale e PID, configurabili sia in modalità diretta che inversa, assicurando massima flessibilità applicativa. Il controllo PID con auto-ottimizzazione permette il mantenimento costante dei parametri operativi anche in presenza di condizioni variabili.

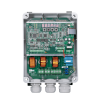

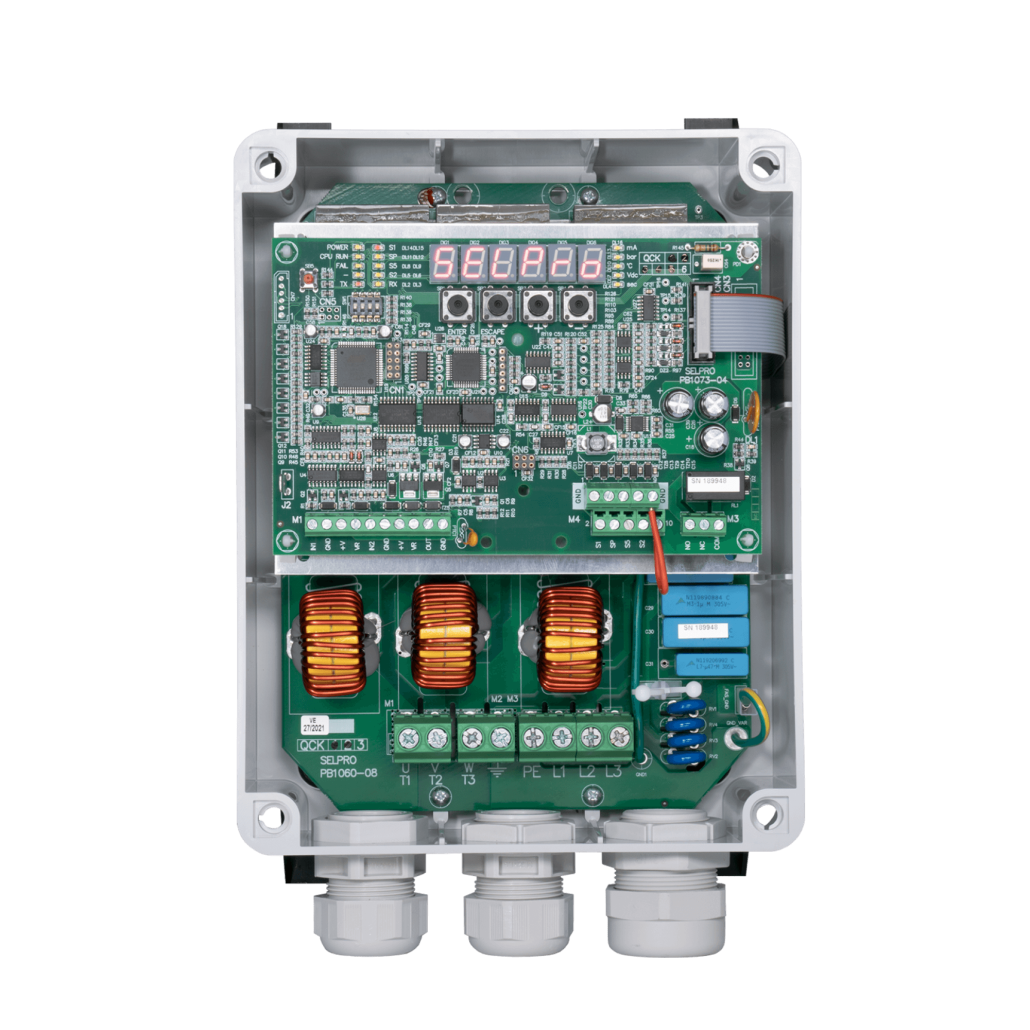

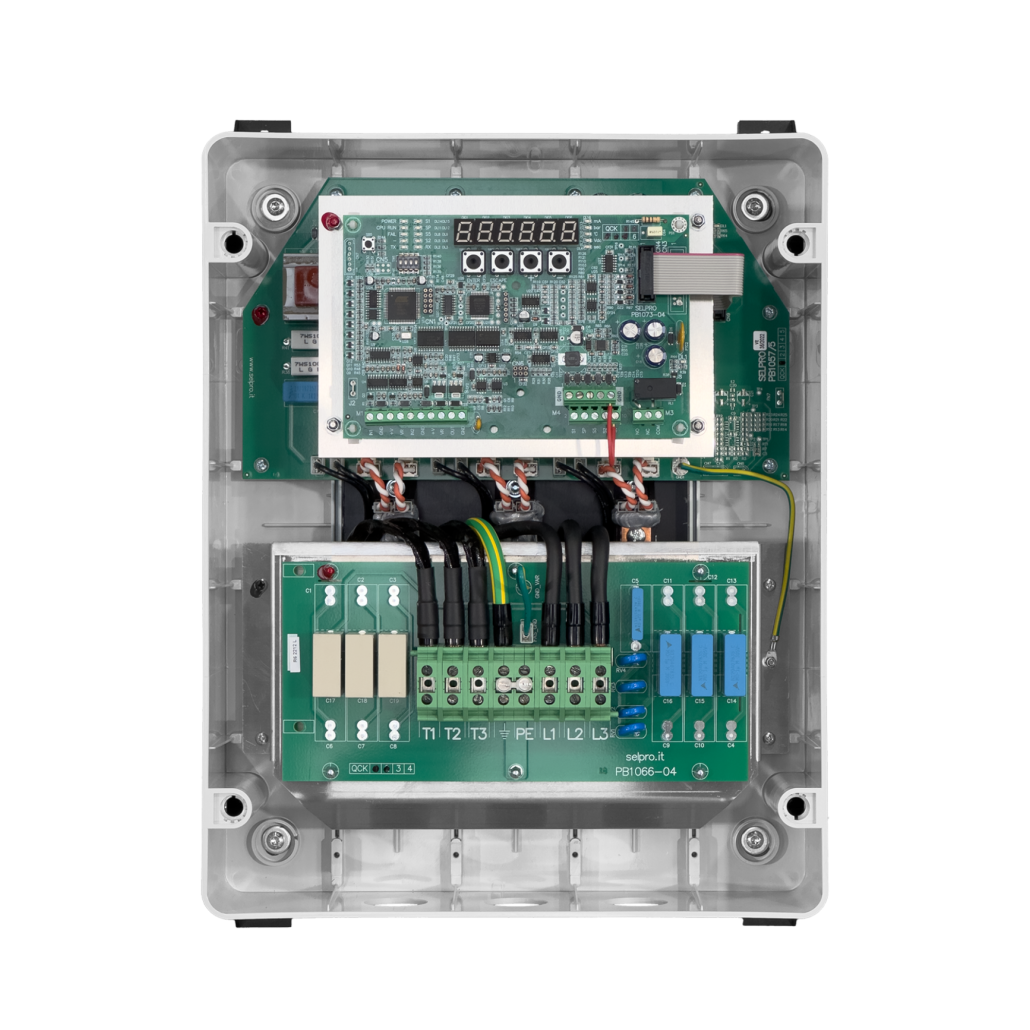

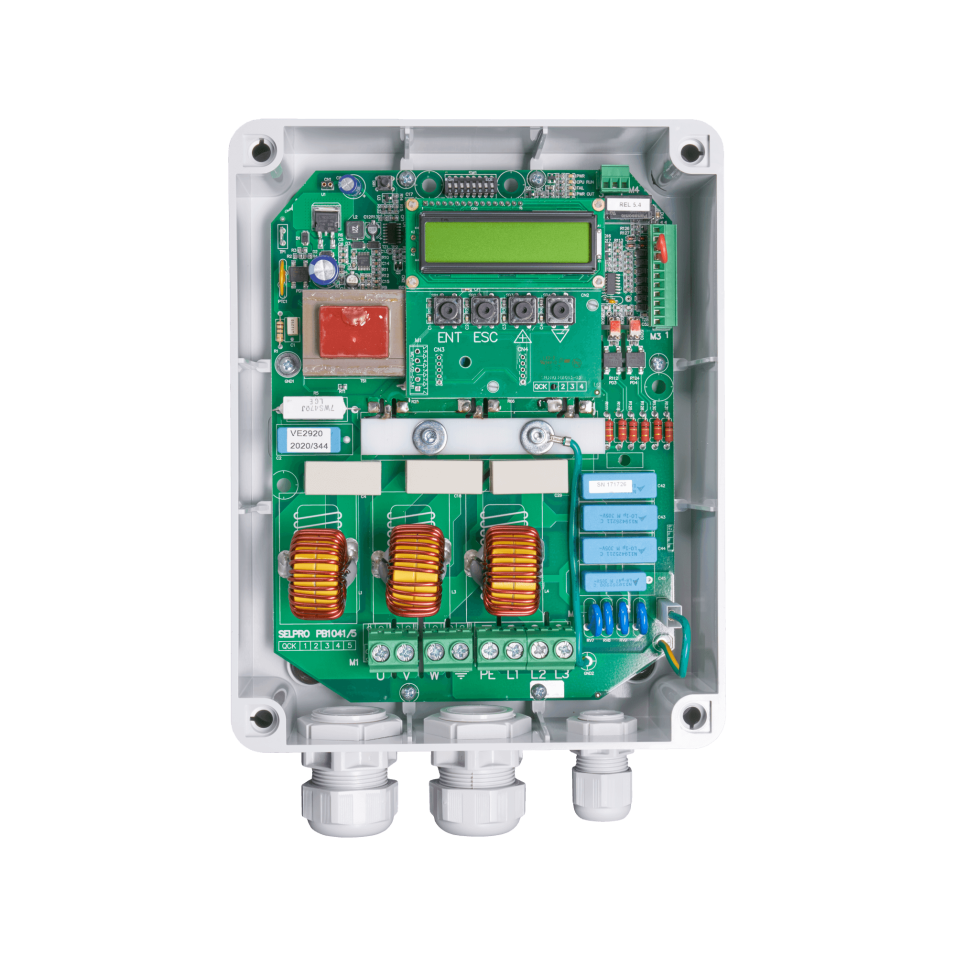

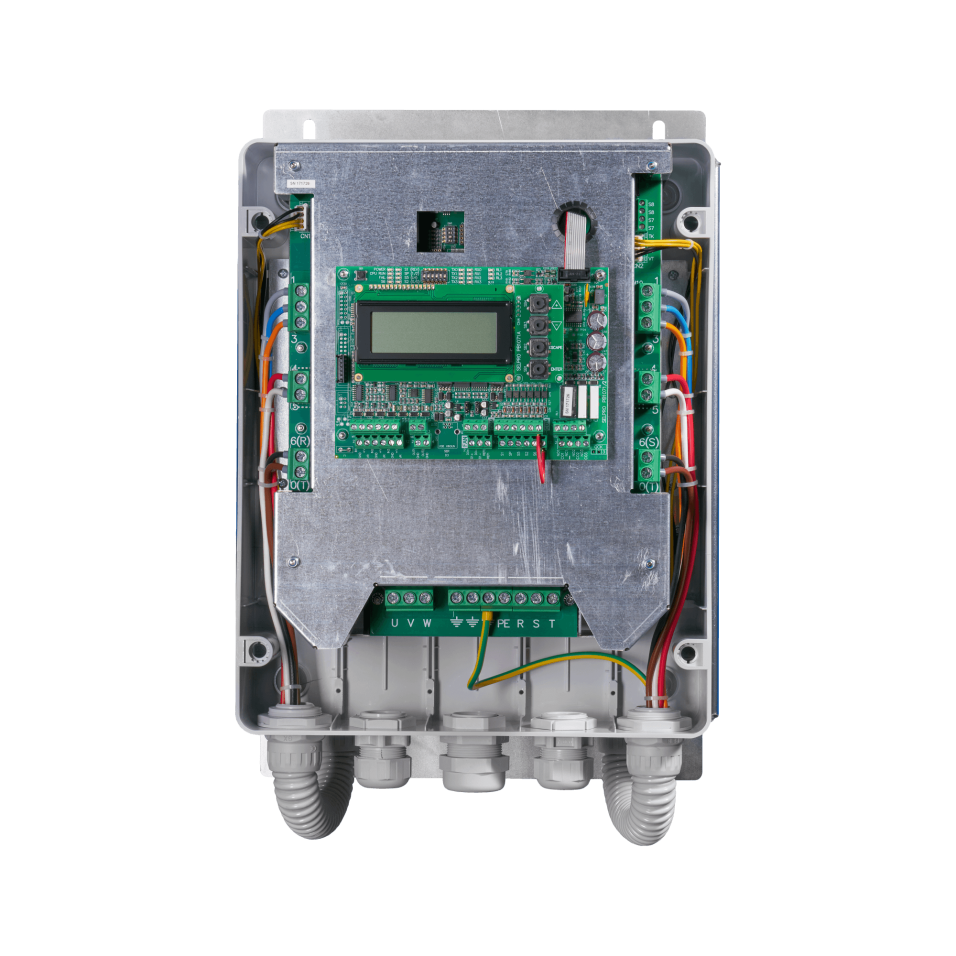

Dal punto di vista hardware, RGM utilizza alternistori bidirezionali (TRIAC) nelle taglie fino a 28 A, scelti per la loro affidabilità nella gestione di correnti medio-alte. Nelle taglie superiori vengono impiegate coppie di SCR (Silicon Controlled Rectifier), ideali per applicazioni ad alta potenza grazie alla loro elevata capacità di conduzione.

Un elemento distintivo dell’architettura di RGM è il sistema di innesco degli SCR/alternistori, realizzato con trasformatori per impulsi, progettati per garantire ampia area d’impulso. Questo approccio, a differenza delle soluzioni basate su optotriac, rende indipendente il comando dalla tensione di alimentazione, migliorando la stabilità e l’affidabilità anche in presenza di fluttuazioni di rete.

Il regolatore dispone di 2 ingressi analogici, compatibili con segnali 0/20 mA, 4/20 mA, 0/10 Vdc, 0/5 Vdc e sonde NTC (-10/+90 °C). È possibile configurare due banchi di parametri operativi più un banco dedicato alla modalità adiabatico, che consente il controllo dinamico di sistemi Wet & Dry in base a condizioni ambientali, temperatura e orari.

La gestione ausiliaria è affidata a 5 contatti on-off programmabili, utilizzabili per funzioni come Start/Stop remoto, protezione TK, limite notturno, cambio setpoint e modalità inversa. È presente un relè configurabile per la segnalazione di allarmi o il comando di dispositivi ausiliari.

RGM offre anche un’uscita proporzionale 0(1)-10 Vdc per il pilotaggio di dispositivi slave e un’uscita on-off dedicata al comando del sistema adiabatico, permettendo il coordinamento completo tra ventilazione e raffreddamento evaporativo.

Il regolatore è predisposto per l’integrazione con sistemi BMS tramite connessione Modbus RTU slave, attivabile con plug opzionale, per la gestione remota dei parametri.

La protezione contro sovratensioni e disturbi elettromagnetici, unita al grado di protezione IP55, rende RGM ideale per ambienti difficili, resistendo a polvere, umidità e vibrazioni.

Funzioni speciali come sbrinamento e protezione antigelo aumentano la flessibilità operativa, rendendo RGM una soluzione completa e affidabile per impianti di ventilazione, drycooler, condensatori e chiller.

Ingressi, uscite e connettività

- Ingressi analogici: 2 ingressi compatibili con 0/20 mA, 4/20 mA, 0/10 Vdc, 0/5 Vdc, NTC (-10/+90 °C)

- Contatti ausiliari on-off: 5 contatti programmabili (Start/Stop, TK, limite notturno, cambio setpoint, modalità inversa)

- Relè: 1 relè configurabile per allarme o logiche esterne

- Uscita proporzionale: 0(1)-10 Vdc per dispositivi slave

- Uscita on-off: comando sistema adiabatico

- Connessione Modbus RTU: slave (su plug opzionale)

Caratteristiche speciali

- Controllo adattivo e preciso per garantire che i parametri operativi restino all’interno del setpoint definito, anche in presenza di variazioni significative del carico.

- Il dispositivo offre 2 setpoint di regolazione impostabili al limite minimo o al limite massimo e la possibilità di configurare 2 banchi di parametri personalizzabili, tra cui limite notturno, salti di velocità, velocità massima e minima, rampa di accelerazione e altri parametri operativi per una gestione flessibile e adattabile alle diverse esigenze.

1 output 0-10V indicati per asservire ad una unità principale (Master) una o più unità Slave, o per la gestione di un sistema adiabatico con un set di parametri dedicato.

- 0-10 Vdc

- Sistema adiabatico

- 1 output ON/OFF indicato per l'attivazione di un sistema adiabatico

- Plug aggiuntivo opzionale per connessione isolata BMS Modbus RTU