Descrizione

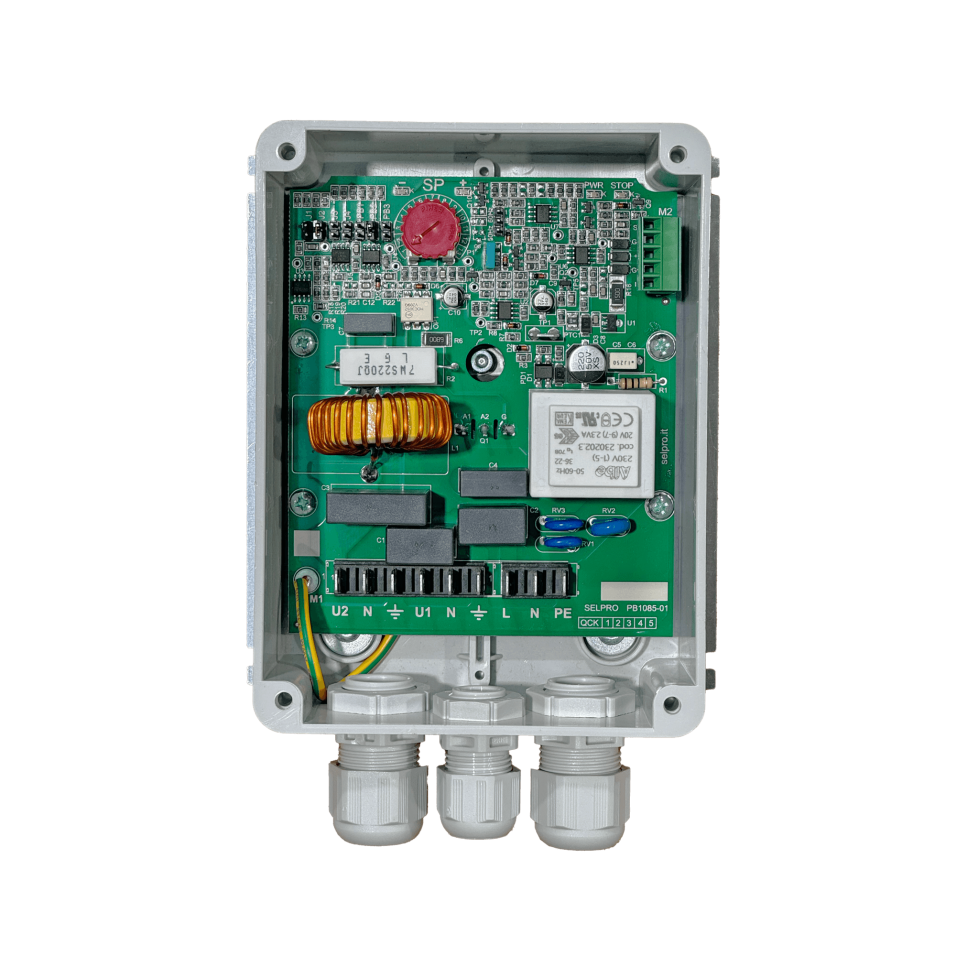

ESK è un sistema quadro di controllo digitale progettato per il controllo avanzato della velocità di motori asincroni monofase, con funzionamento in modalità master o slave e regolazione proporzionale tramite parzializzazione a taglio di fase bilanciata rispetto alla rete. È particolarmente adatto per applicazioni HVAC/R come drycooler e condensatori, dove garantisce un controllo preciso, affidabile e modulare in base alle esigenze operative dell’impianto.

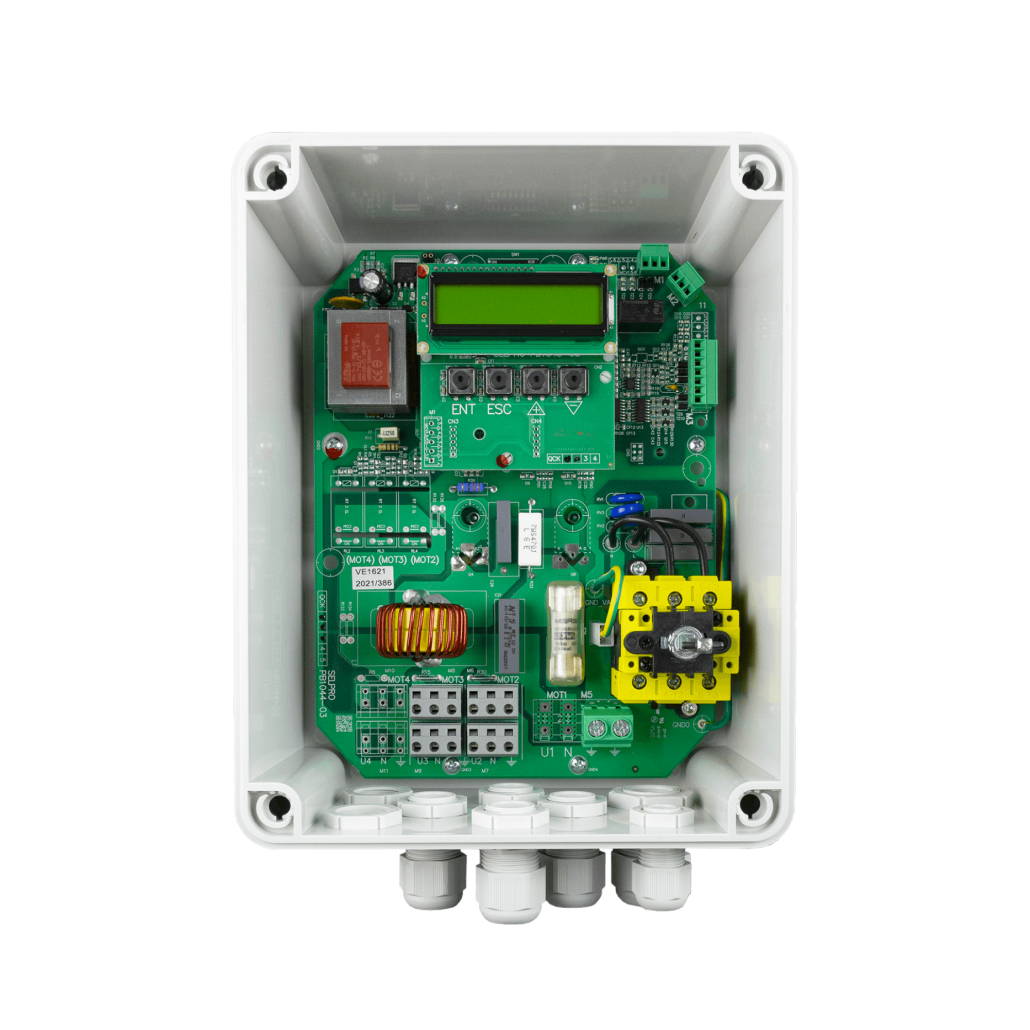

Basato su un’architettura compatta e autonoma, ESK integra un sezionatore di linea e non richiede componenti esterni per la messa in servizio. È disponibile in versione IP55 per ambienti gravosi o in versione IP00 per installazione all’interno di quadri elettrici.

Il sistema consente la gestione di 15 configurazioni predefinite, selezionabili per adattarsi rapidamente alle diverse logiche di funzionamento. È dotato di due ingressi analogici in modalità master, compatibili con trasduttori di pressione 4-20 mA, 0,5-4,5 V o sonde NTC (range di lettura-10 °C / 90 °C). In modalità slave accetta segnali 0-10 V, 4-20 mA e dispone di un ingresso PWM indipendente. È inoltre presente un terzo ingresso analogico (IN3), personalizzabile su richiesta, che può essere configurato per accettare segnali 0-5 V, 0-10 V, 4-20 mA o NTC, offrendo ulteriore flessibilità nelle applicazioni avanzate

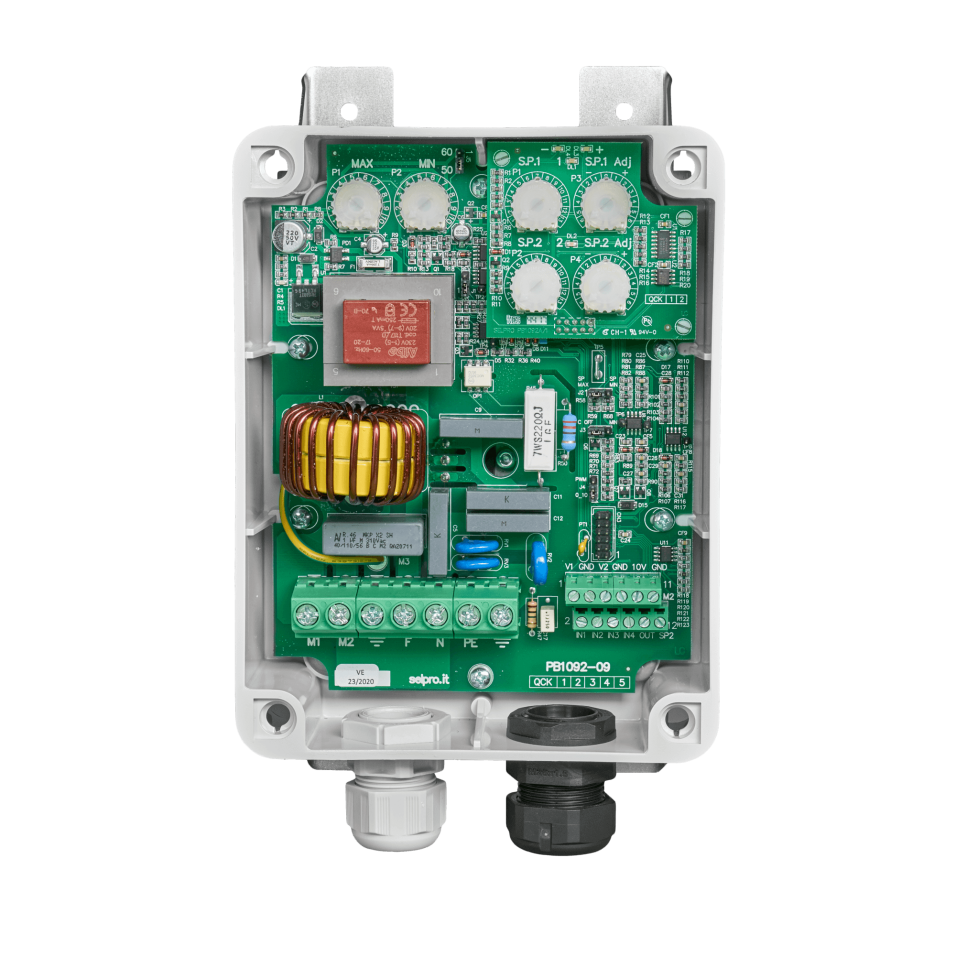

Il regolatore gestisce due setpoint indipendenti, con la possibilità di configurare due banchi di parametri personalizzati: limite notturno, velocità minima e massima, salti di velocità e rampe di accelerazione. Questo permette una regolazione estremamente flessibile, adattabile a differenti profili applicativi.

Per il supporto di logiche evolute, ESK dispone di tre contatti on-off programmabili, utilizzabili per funzioni come Start/Stop, cambio setpoint, regolazione inversa o modalità pompa di calore. L’uscita ausiliaria 0-10 V permette il pilotaggio diretto di dispositivi slave, sincronizzando più elementi all’interno del sistema HVAC.

Il regolatore integra anche un relè in scambio con funzioni configurabili, utile per la gestione degli allarmi o di altri componenti ausiliari. Le protezioni sugli ingressi di comando e contro sovratensioni di rete assicurano affidabilità operativa elevata e continuità di funzionamento.

L’integrazione con sistemi di supervisione è possibile tramite plug opzionale Modbus RTU, che abilita il monitoraggio remoto e l’interconnessione con BMS o controller di impianto.

Ingressi, uscite e connettività

- Ingressi analogici (master): 2 ingressi per trasduttori 4-20 mA, 0,5-4,5 V o sonde NTC (-10°C / +90°C) 1 ingresso per trasduttori 4-20 mA, 0,5-4,5 V o sonde NTC per funzioni speciali

- Ingressi (slave): 0-10 V, 4-20 mA, 1 segnale PWM indipendente

- Contatti ausiliari on-off: 3 contatti programmabili (Start/Stop, cambio setpoint, funzione inversa)

- Uscite ausiliarie: 1 uscita 0-10 V per pilotaggio di dispositivi slave

- Relè: 1 relè in scambio configurabile

- Connessione Modbus RTU: disponibile tramite plug opzionale

Caratteristiche speciali

- Sono disponibili due diversi setpoint di regolazione e due set di parametri associati. È possibile selezionare uno o l'altro setpoint, e relativo set di parametri, tramite un ingresso On/Off.

1 output 0-10V indicato per asservire ad una unità principale (Master) una o più unità Slave

- 0-10 Vdc

- Supporto BMS Modbus RTU con plug (opzionale) per un’integrazione semplice con sistemi di supervisione e monitoraggio remoto avanzato.