Dry Cooler

Dry Cooler solutions.

Fan control in dry coolers - including dry, wet or hybrid systems - in industrial and commercial systems is essential to optimize energy efficiency, ensure stability and prolong the useful life of the equipment.

Selpro provides solutions for active electronic management and ventilating system control, ensuring optimal functioning conditions by optimizing dry cooling and avoiding water consumption; this also significantly benefits the environment.

Compared to traditional on/off controls that continuously alternate between zero and maximum power, proportional fan control means airflow can be adjusted to meet the real cooling requirements. Fans work at lower speeds with partial loads or lower outdoor temperatures, making significant energy savings, optimizing operation of the refrigeration compressor – the most energy-hungry part of the system – and reducing operating costs.Free cooling technology helps reduce costs as outdoor air is used to cool the battery without the compressor.

Accurate speed control means that optimal temperatures can be maintained so the coolant does not overheat, operating pressure is reduced and operation is stable. Speed modulation also reduces noise and mechanical wear and tear of components like motors and bearings, significantly increasing the life of the equipment and resulting in lower maintenance costs.

Selpro solutions for dry coolers automatically adjust to ambient conditions like changes in temperatures and humidity. For example, in colder months, the fans operate at reduced speeds, while airflow increases in warmer periods to ensure uninterrupted, efficient cooling.

In adiabatic systems, Selpro can provide advanced control to manage on-off devices, modulating control actuators, water sprays and adiabatic evaporative panels.In high temperature conditions, the system lowers incoming air temperatures through controlled evaporation, improving efficiency and reducing water consumption. Automated management optimizes adiabatic activation to suit real ambient parameters, ensuring high performance levels, uninterrupted operation and resource savings. Selpro devices also have anti-legionella systems to guaranteegood hygiene.

Selpro can retrofit obsolete equipment with more high-performing components or replace alternating current fans (AC) with more efficient, quieter electronic switching fans.

Plug & Play technology can simplify installation and integration with existing systems to reduce costs and installation times. The main retrofit solutions include:

- upgrading electrical components to improve performance without replacing the entire system,

- conversion to electronic switching fans for higherenergy efficiency and reducedelectricity consumption

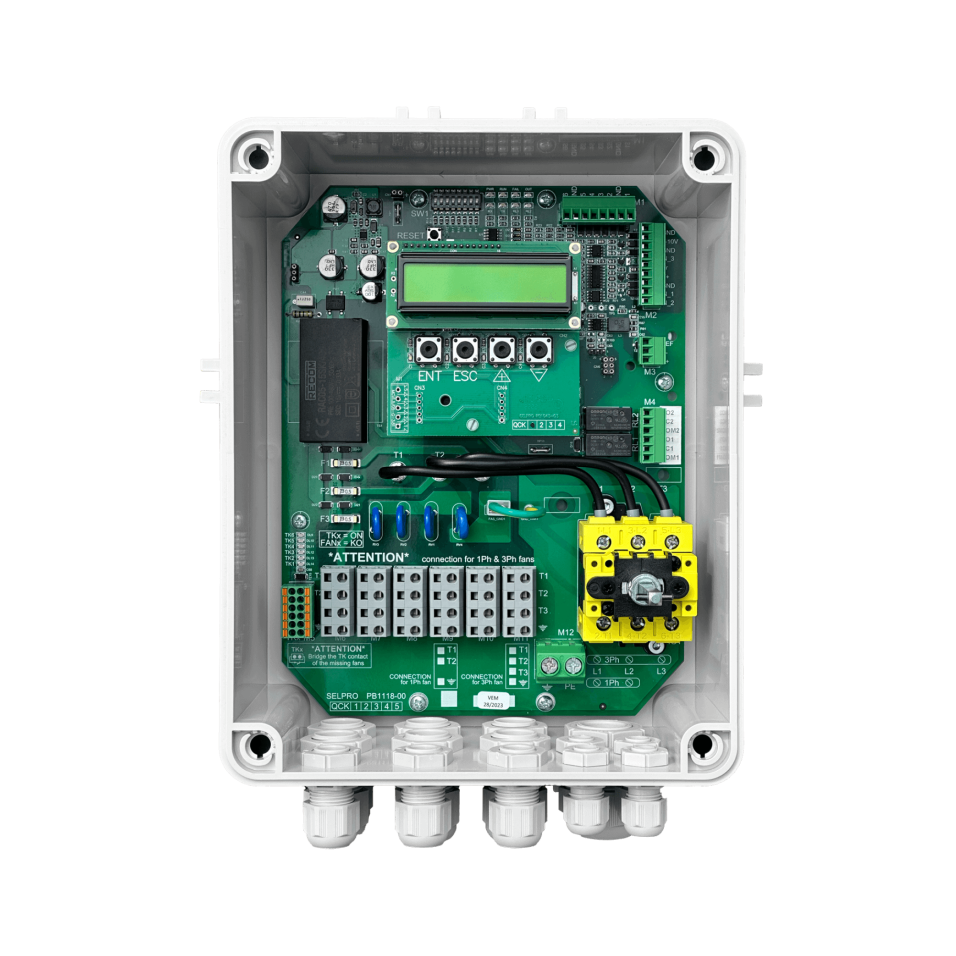

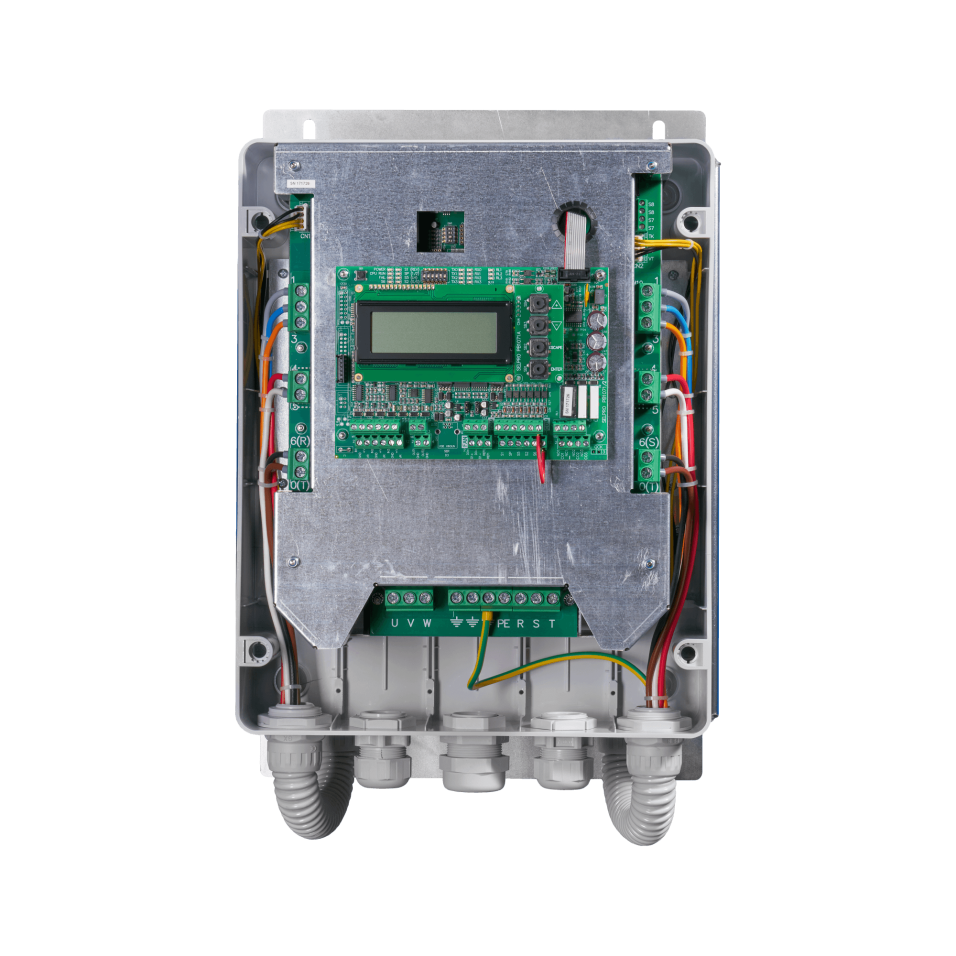

Ideal products for dry coolers

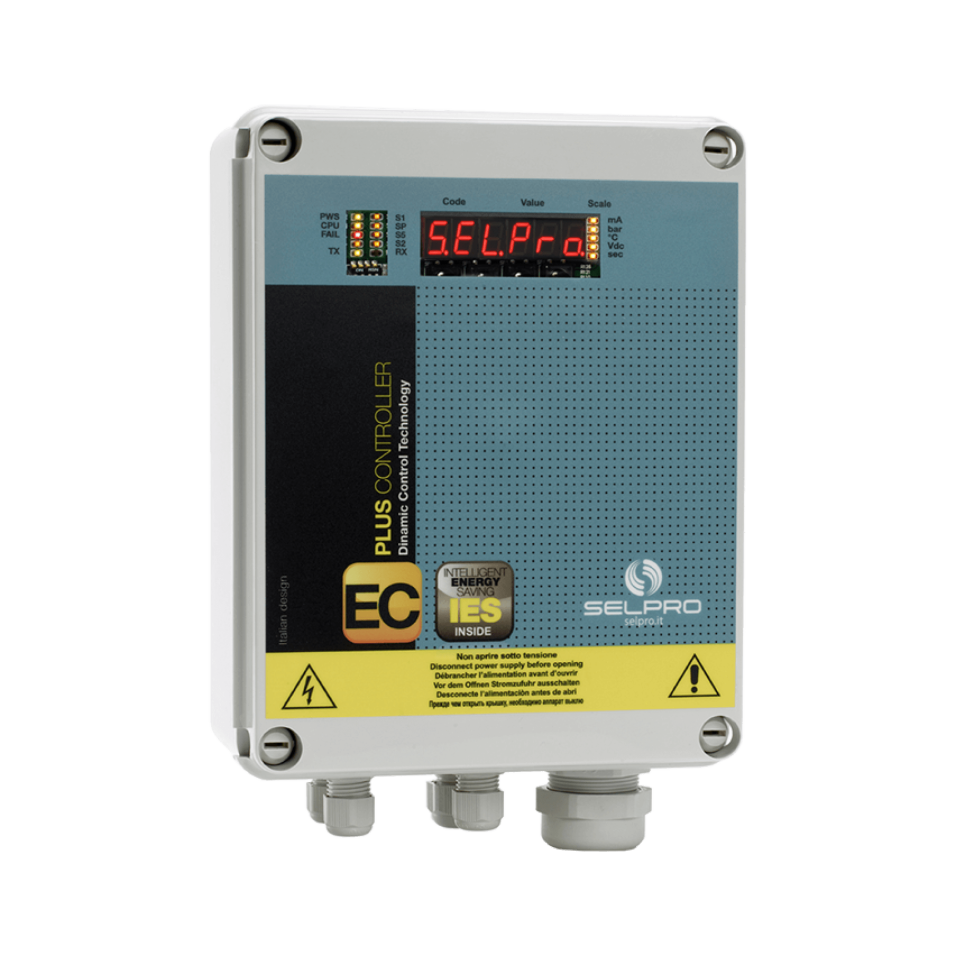

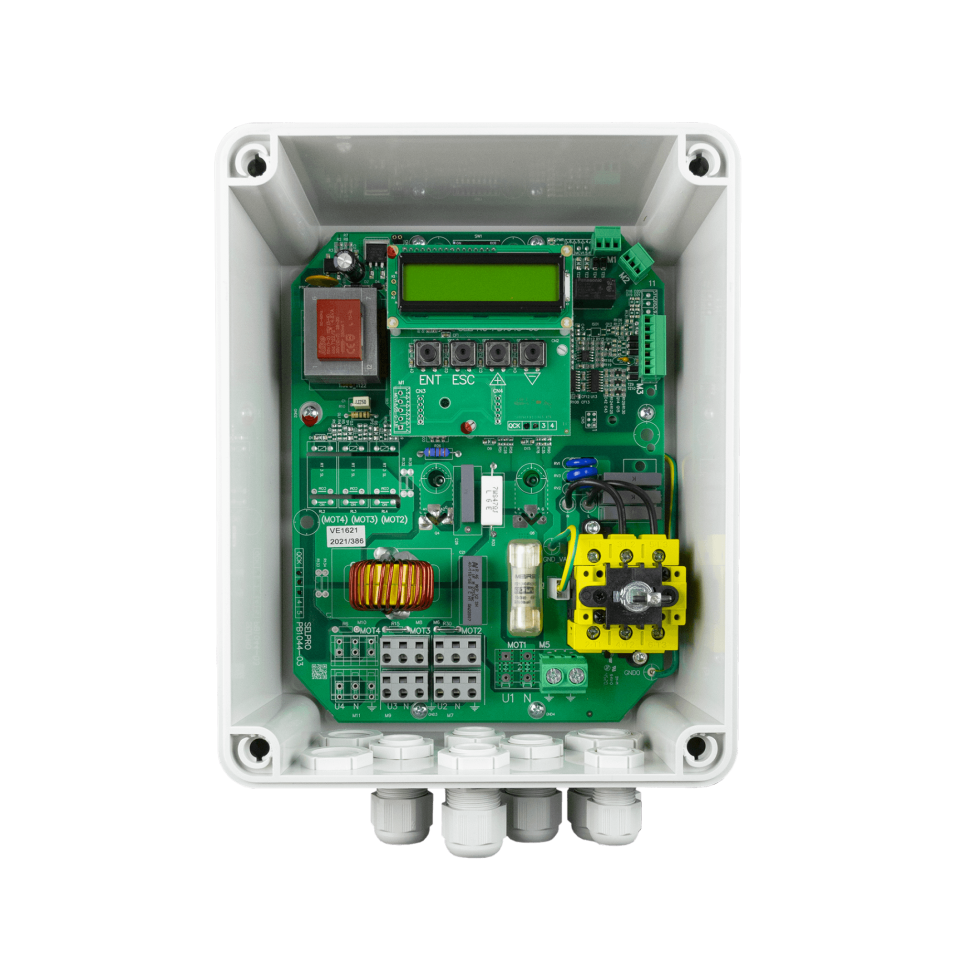

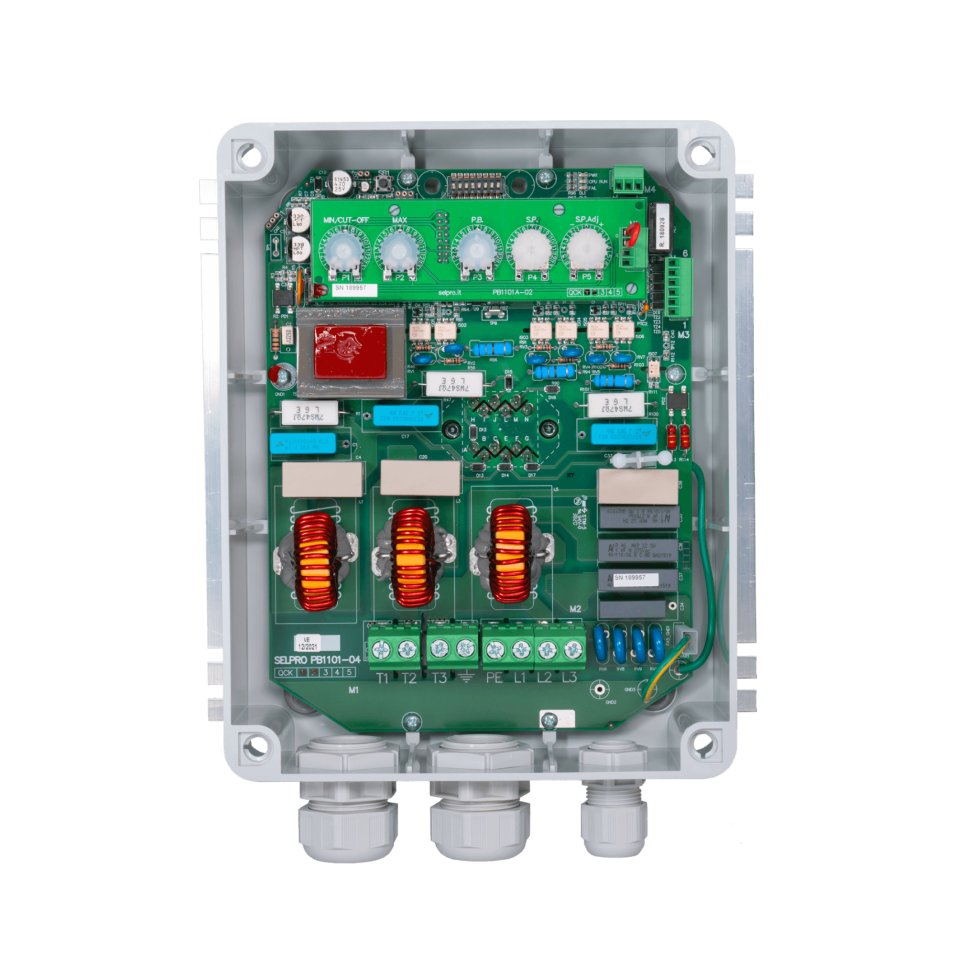

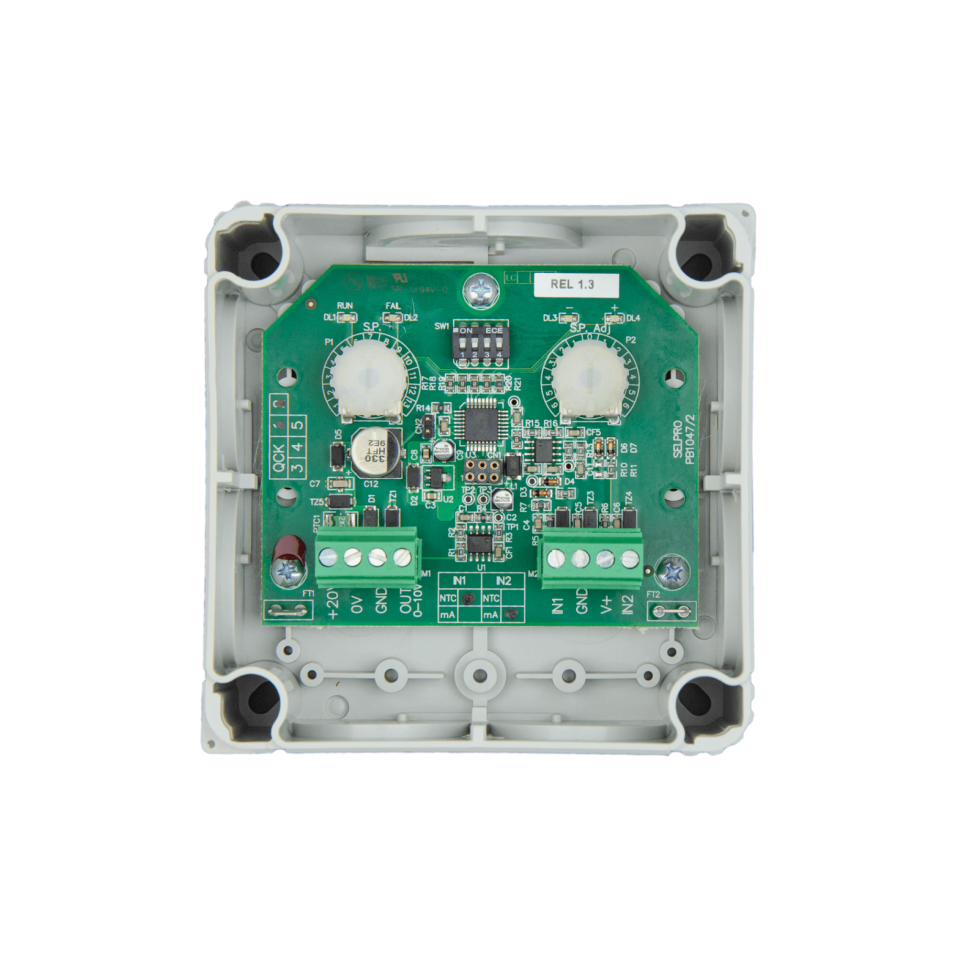

Q Series

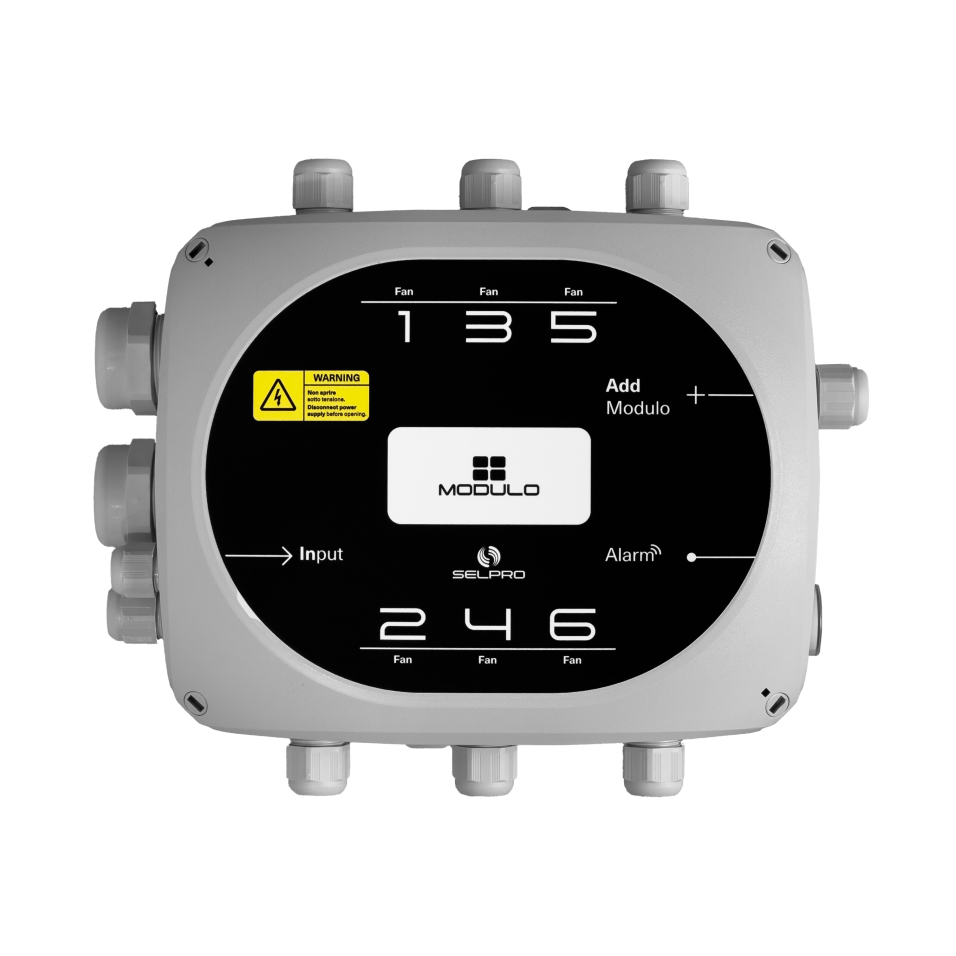

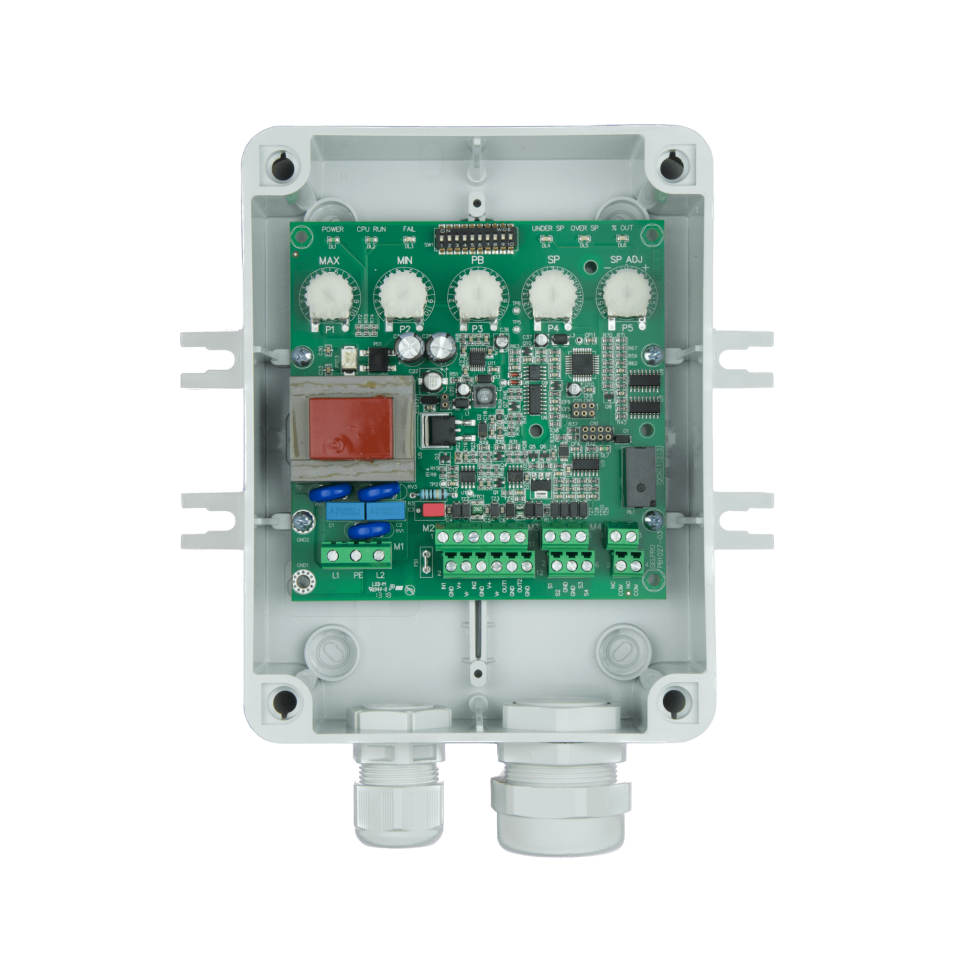

Modulo

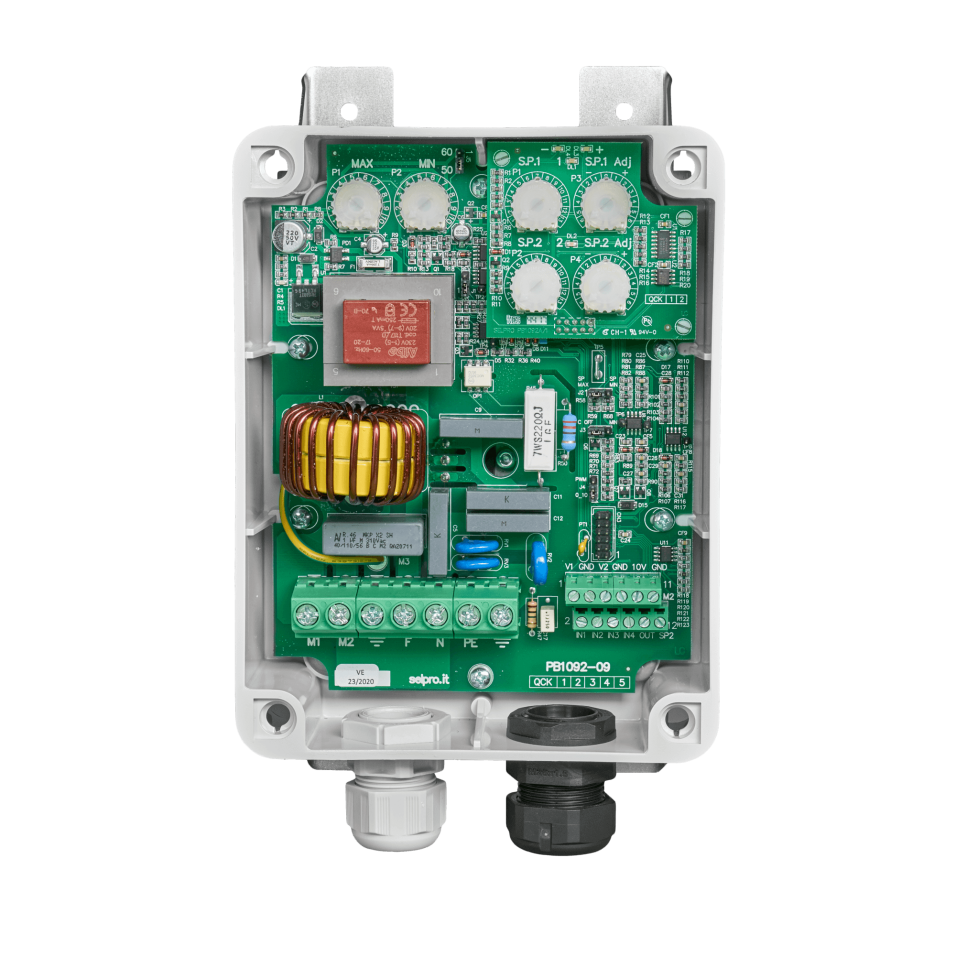

ECB

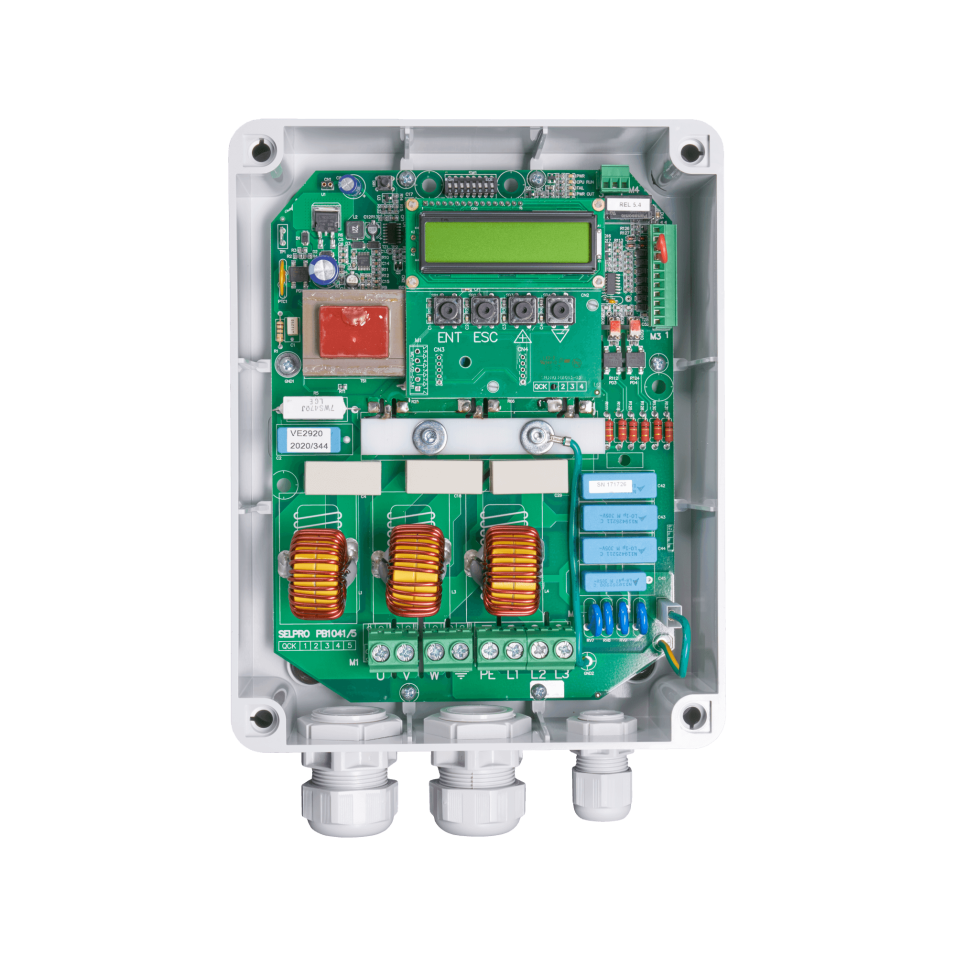

ESY

RDM

ECP

ESK

VTM

ECM

RGM

ECN

ECD

DSV

Most frequently asked questions

Selpro controllers enable dynamic control of fan speed in Dry Cooler systems, improving cooling efficiency and reducing energy consumption, especially during low requirement periods.

Due to the reduction in energy consumption and fan function optimization, our devices help reduce CO2 emissions so that the Dry Cooler systems become more sustainable and environmentally friendly.