Remote condensers

Remote Condenser Solutions

Remote condensers are ventilated heat exchangers used in industrial air conditioning and refrigeration systems to keep operating temperatures stable and improve the energy efficiency of the refrigeration compressor. Since they are installed at a distance from the main unit, they are referred to as remote; they are usually located outdoors to help the heat dissipate and optimize the performance of the whole system.

Inadequate condenser control can reduce efficiency, thereby increasing energy consumption and hindering performance. The advanced management capabilities of Selpro solutions can combat these issues and ensure the constant balancing of temperature, pressure and airflow to optimize the heat exchange capacity of the condenser and improve overall efficiency.

Selpro devices help reduce condenser energy consumption considerably through intelligent fan speed management.

Free cooling technology uses outside air to dissipate heat without having to force compressor function, further reducing energy consumption. The energy use optimization comes into play especially with partial loads when fans operate at lower speeds instead of turning off; this ensures the same performance with significantly lower operating costs and improved overall efficiency.

Another key element of Selpro solutions is the modulated control which controls fan speed in proportion to cooling requirements.. The machine can accurately adapt to changes in temperature and pressure, avoiding abrupt changes in speed which can generate mechanical stress, excessive consumption and premature wear and tear of the components.

Selpro devices also reduce the noise generated by the fans: since the rotation regime is lower on average, noise levels are significantly reduced, improving comfort levels and lowering the impact of sound in the surrounding environment.

In general, energy efficiency optimization and noise reduction help minimize the machine’s impact on the environment so that increasingly stringent corporate sustainability requirements are met and territorial integration is improved.

Ideal products for condensers

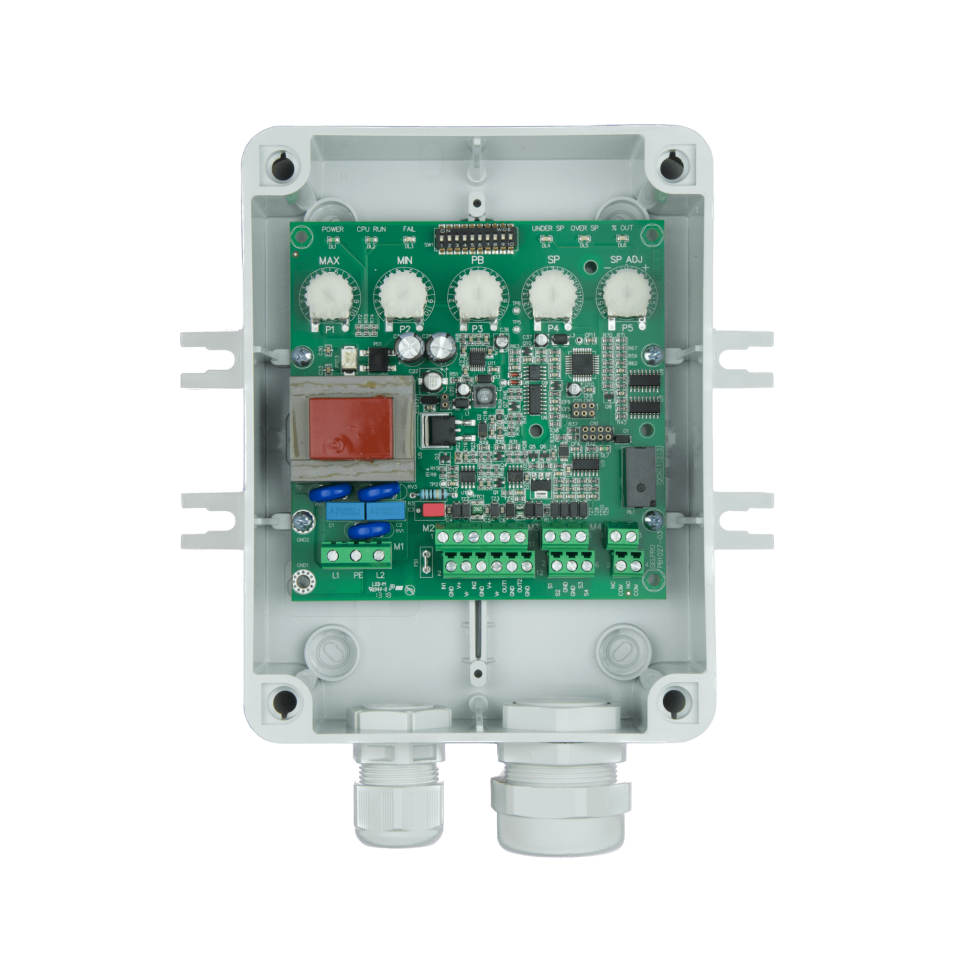

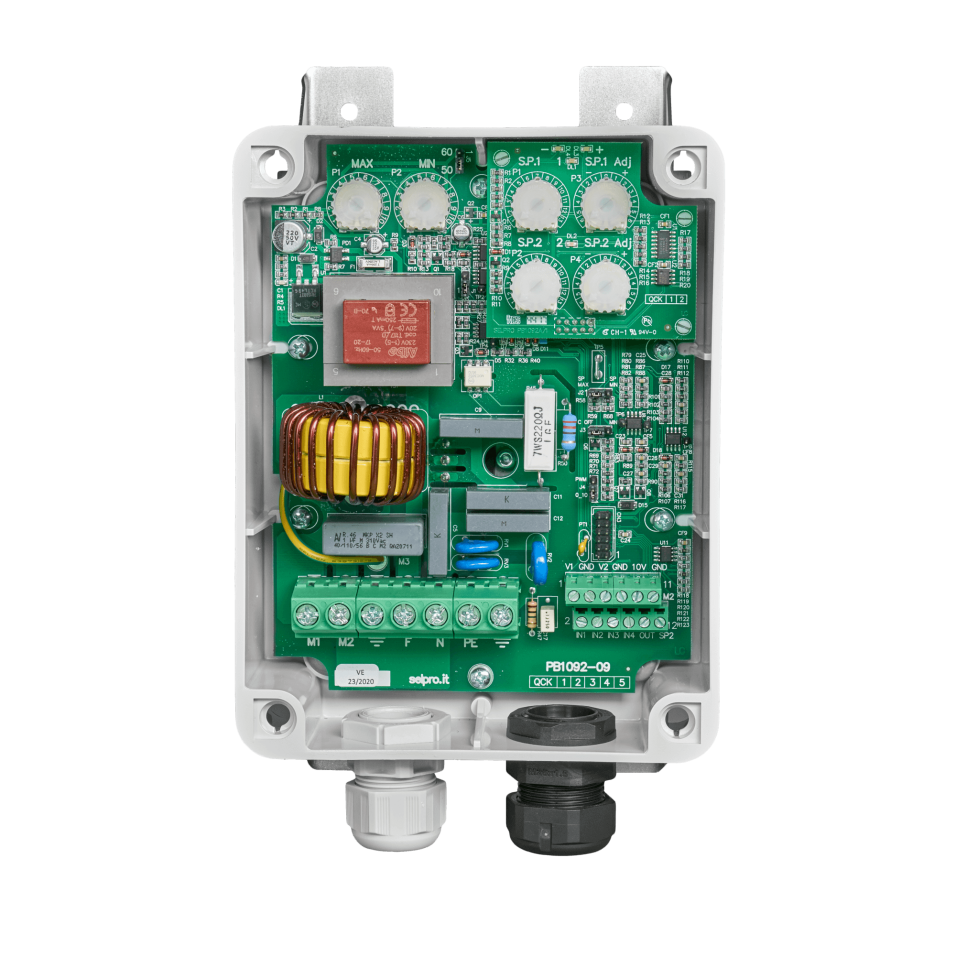

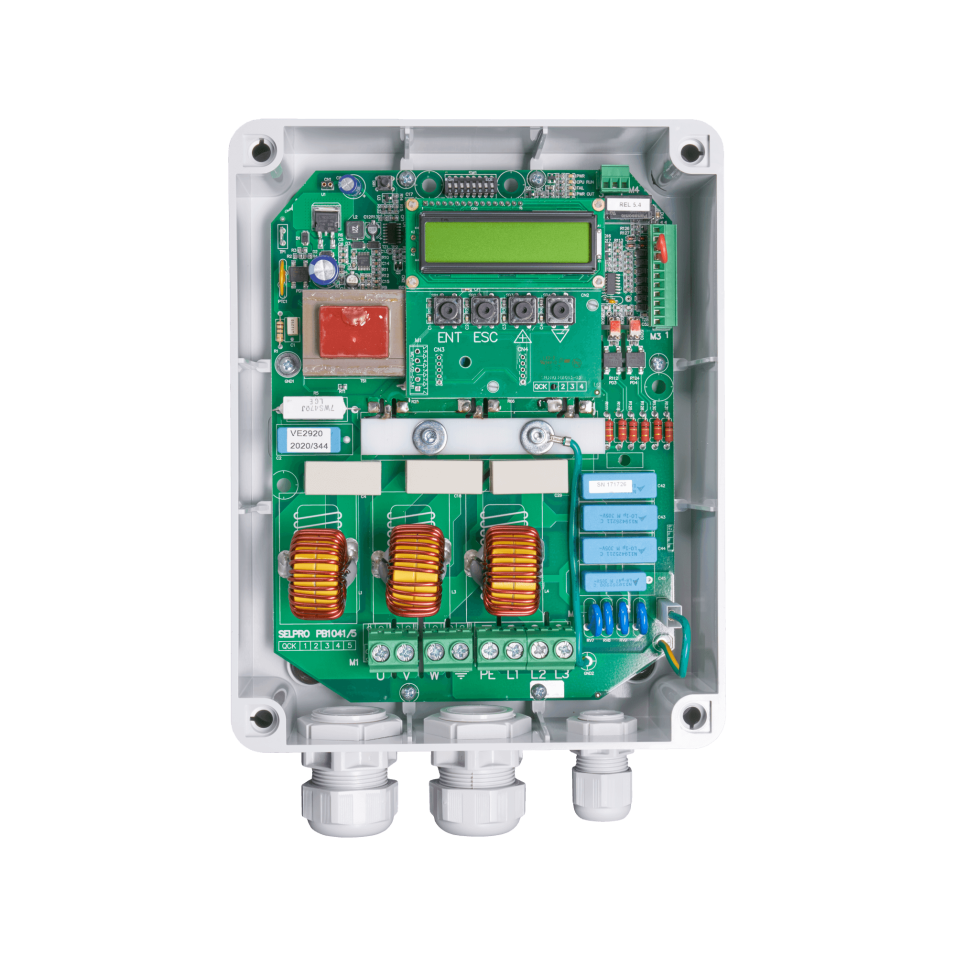

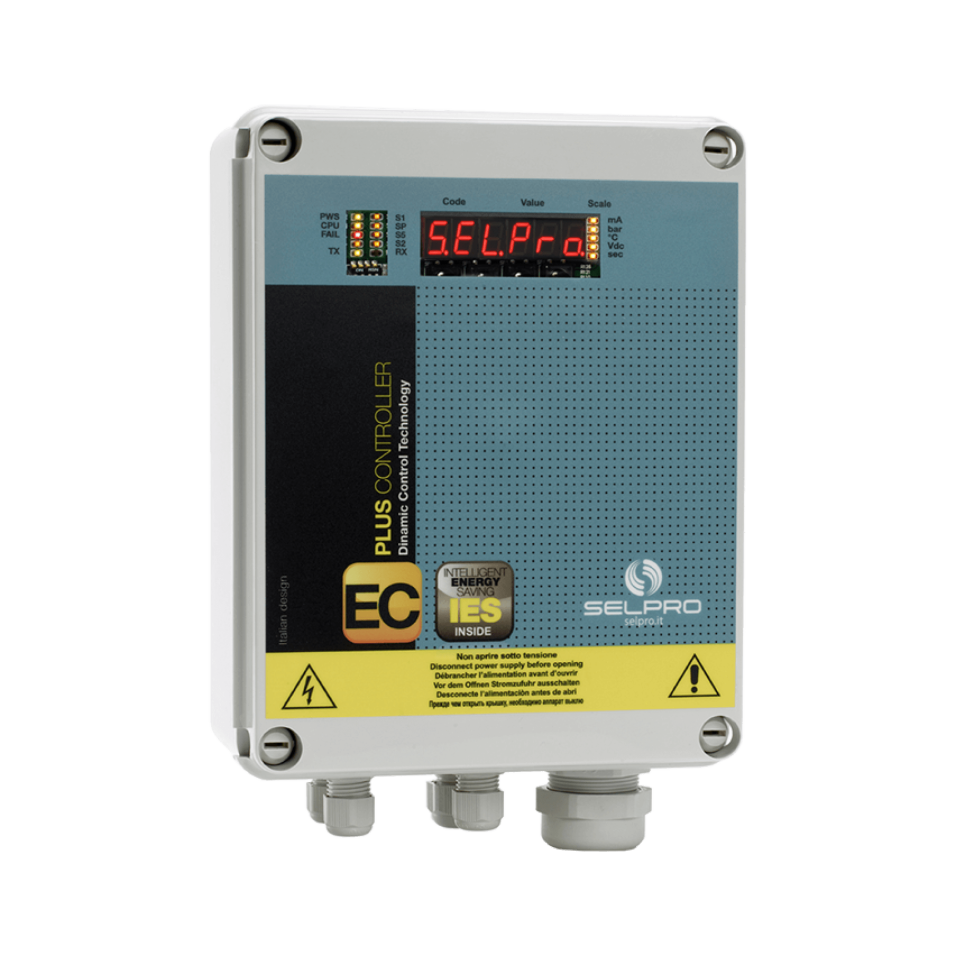

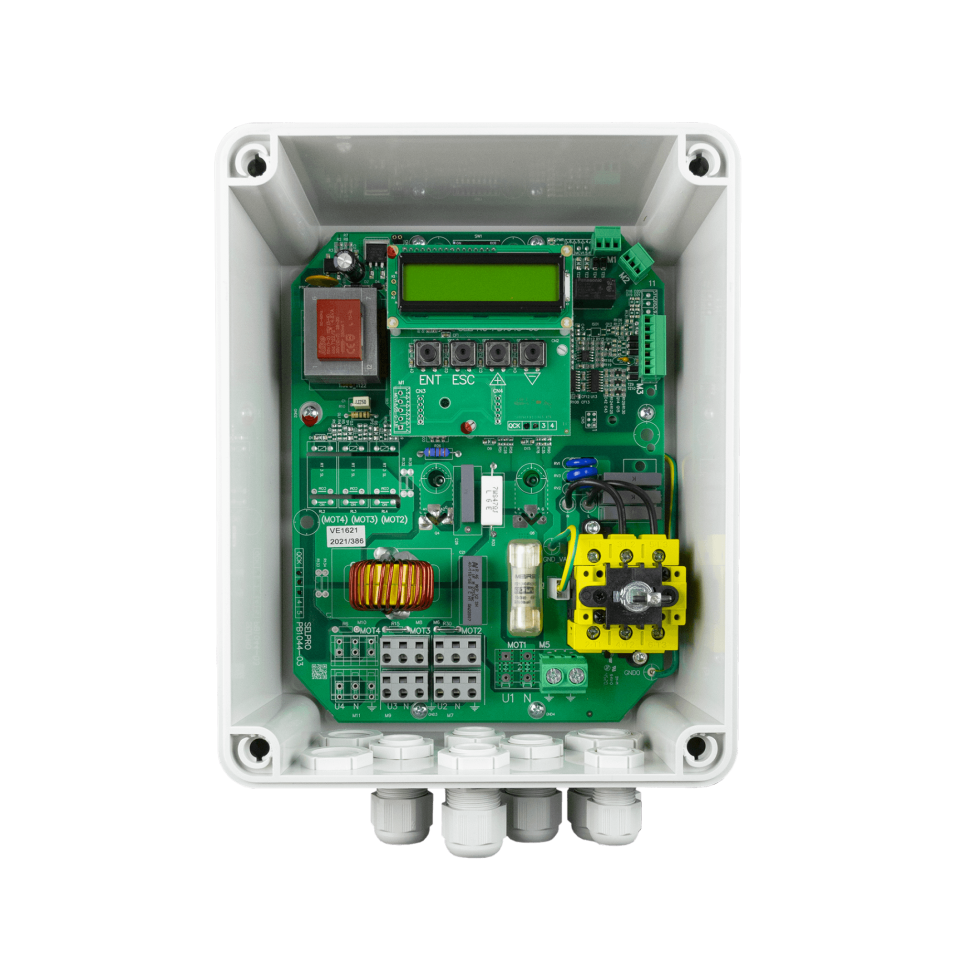

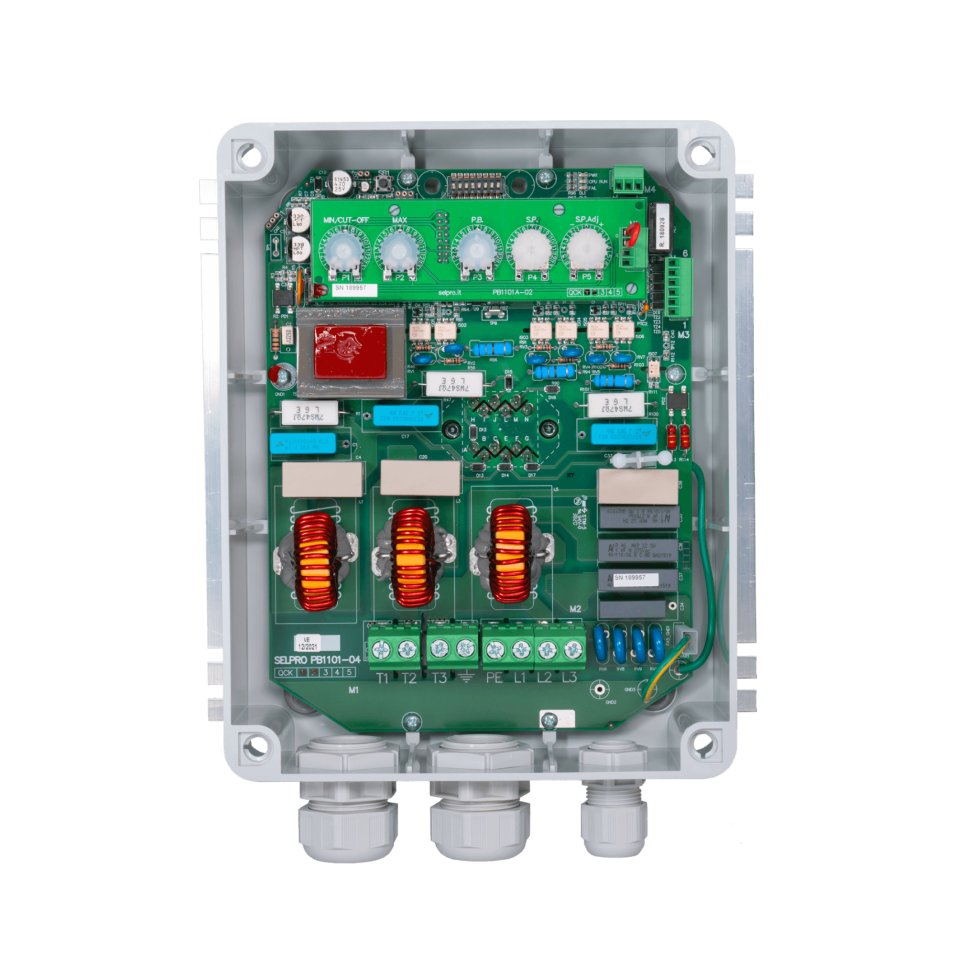

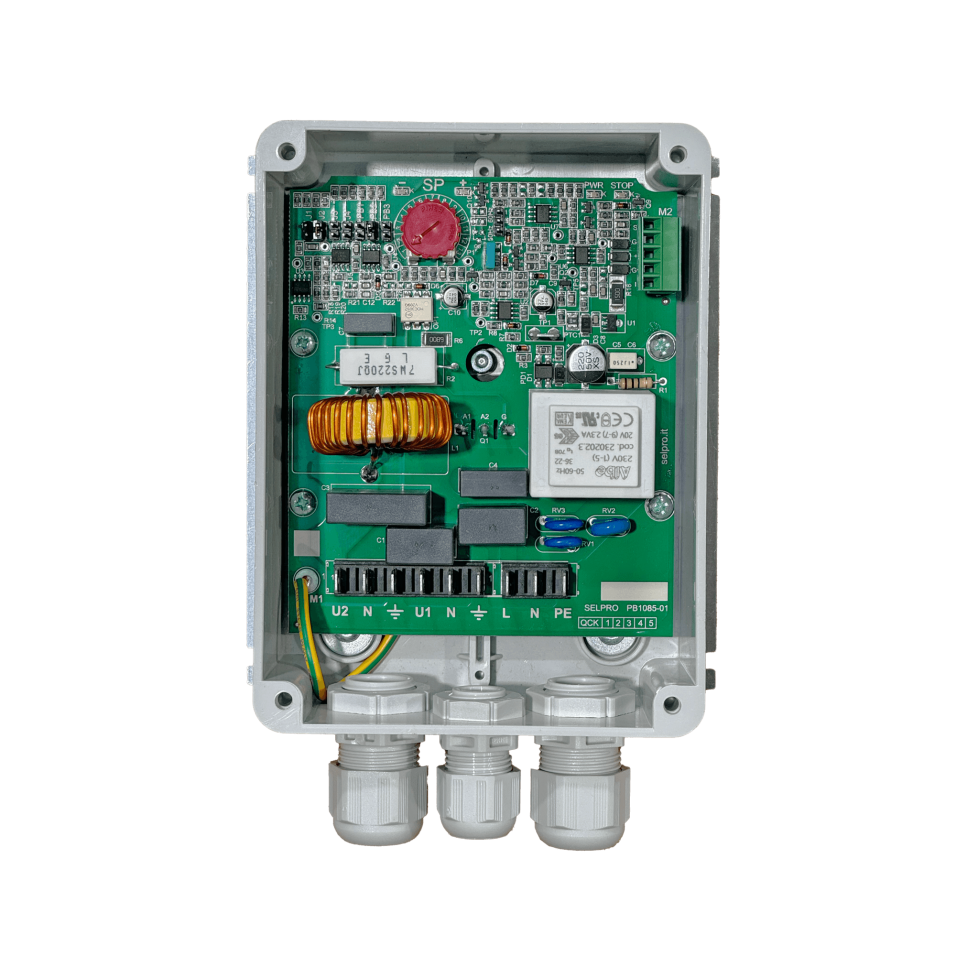

ECB

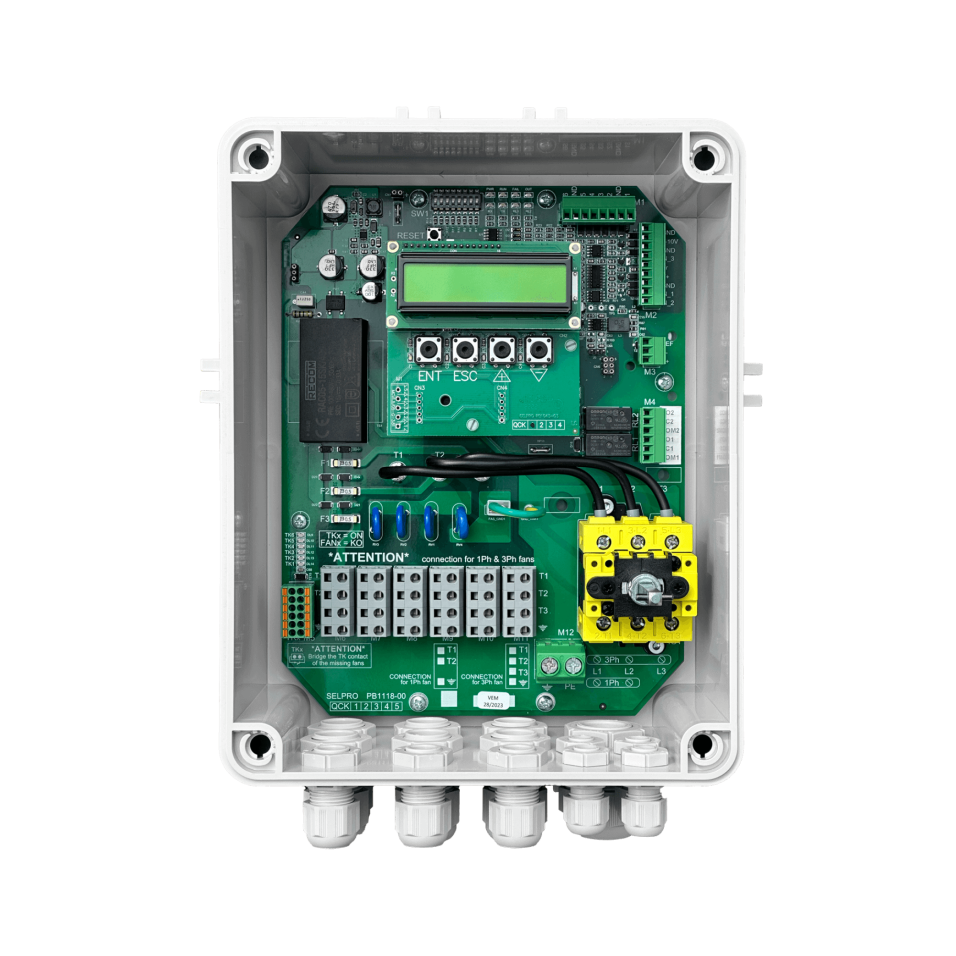

ESY

RDM

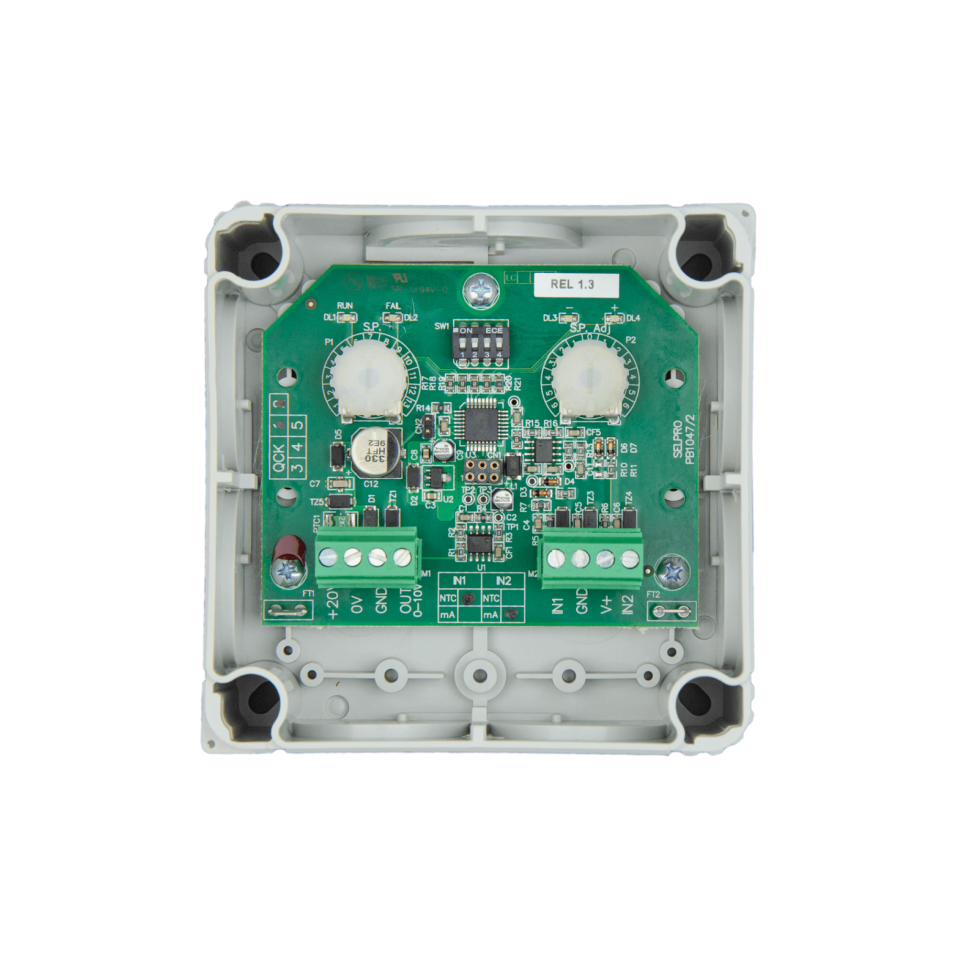

ECP

ESK

VTM

ECM

LCM

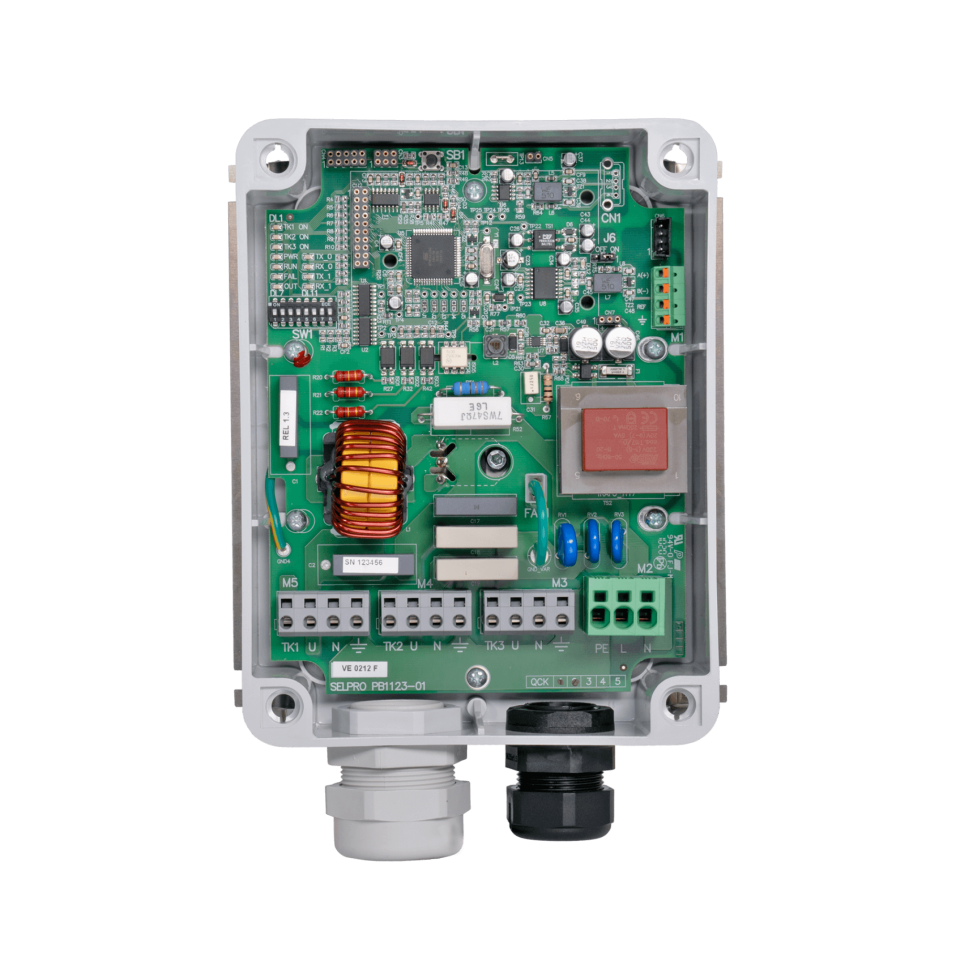

RGM

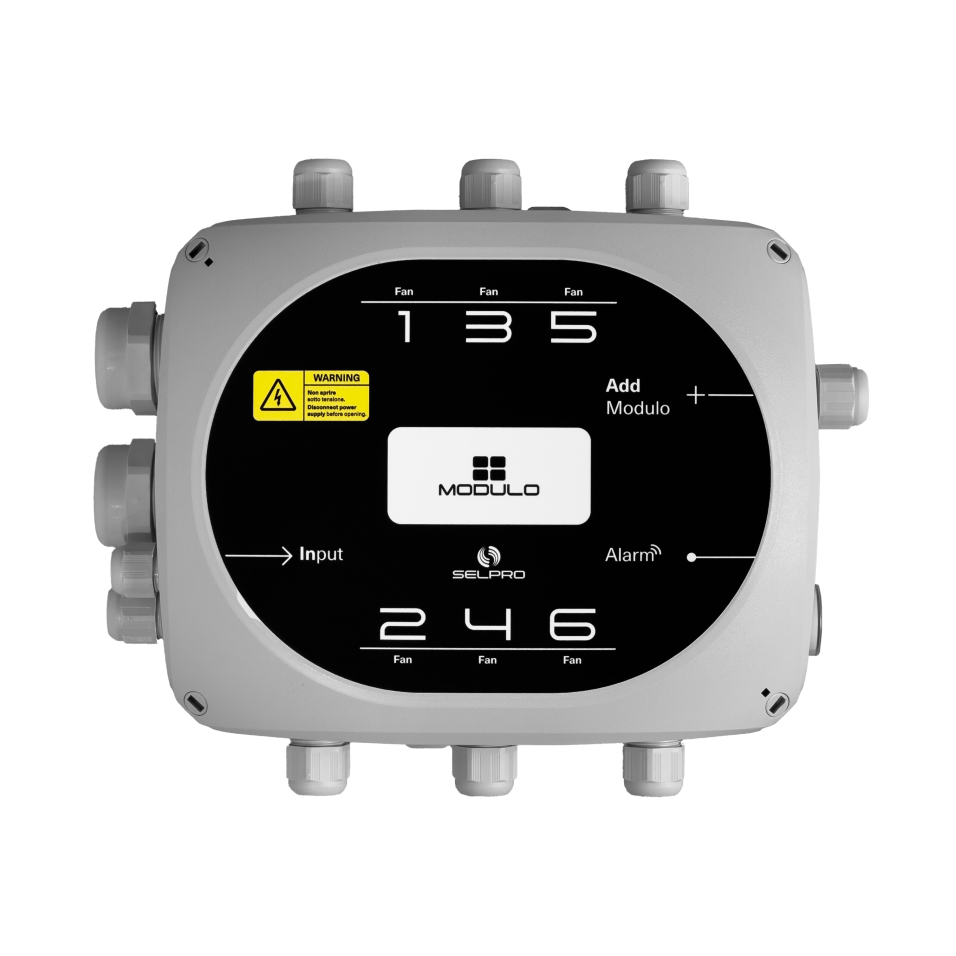

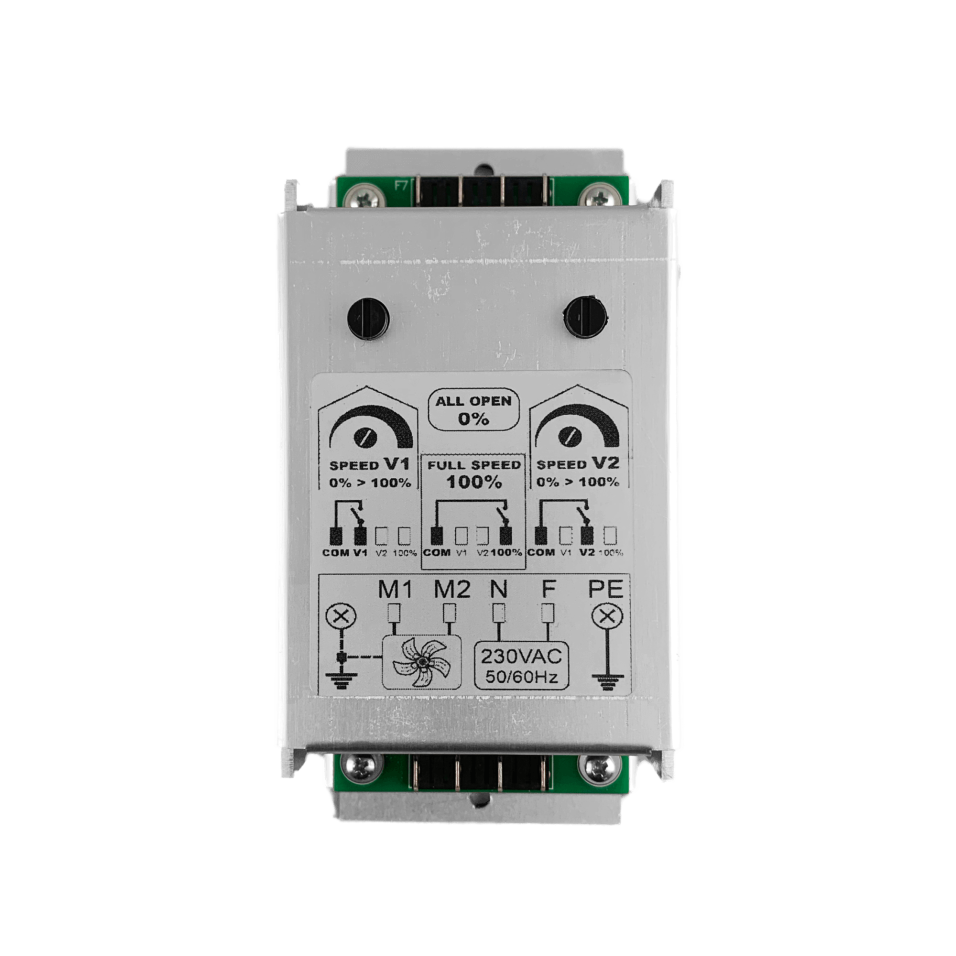

Modulo

ECN

ECD

EMC

EMK

PWM

TRP

Most frequently asked questions

Our controllers, by optimizing fan speed in remote condensers based on the ambient conditions and cooling requirements, ensure significant energy savings and constant cooling.

Yes, our controllers are designed to work in difficult environments, ensuring the accurate, reliable control of the fans, including in challenging environmental conditions with high temperatures or humidity.