Silenziosità, Efficienza senza Compromessi e Conformità totale

La serie DSV Selpro rappresenta la nuova frontiera della regolazione in totale conformità per sistemi ventilanti con motori AC trifase.

Basata su una tecnologia ibrida a gradini di tensione sinusoidale, è progettata per offrire una regolazione fluida e completamente silenziosa, priva di distorsioni armoniche (THD=0%) e pienamente conforme alle normative EMC europee (EN61000-3-12).

A differenza degli inverter e dei regolatori a parzializzazione, DSV assicura assenza totale di rumori acustici (no extra-dB) e disturbi elettrici (THD = 0%), anche in presenza di motori asincroni standard.

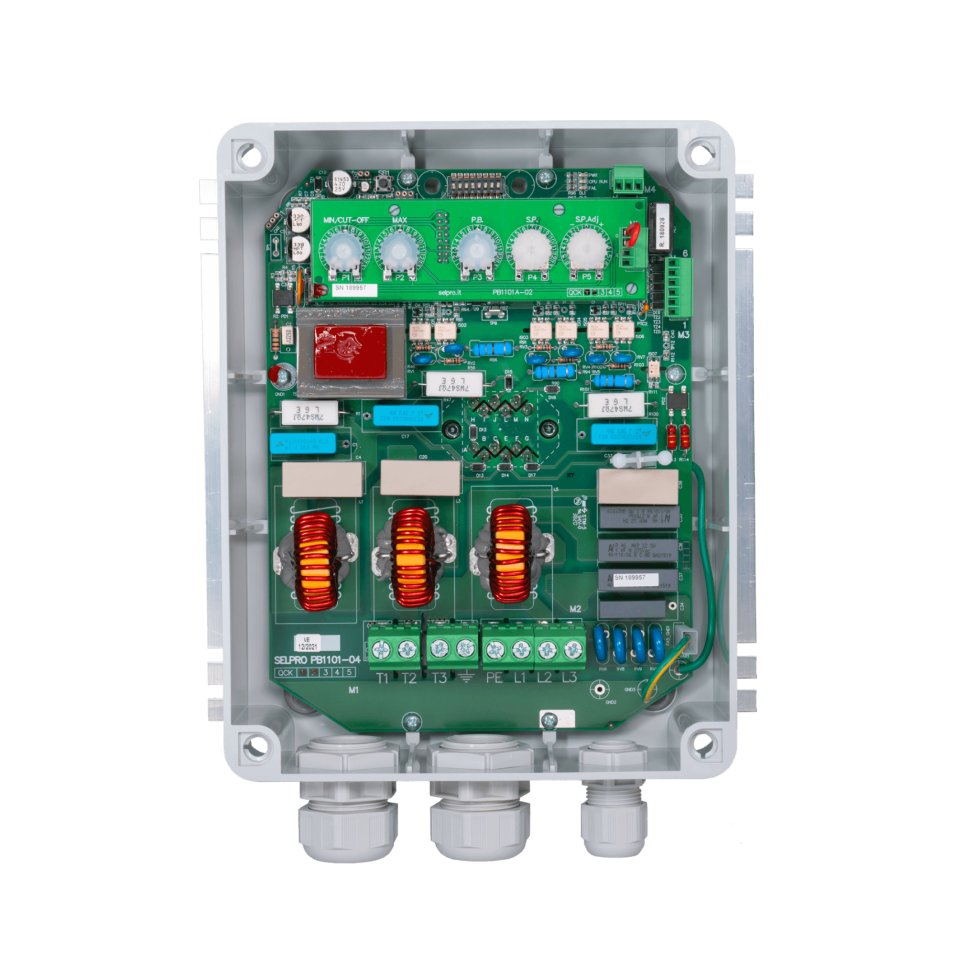

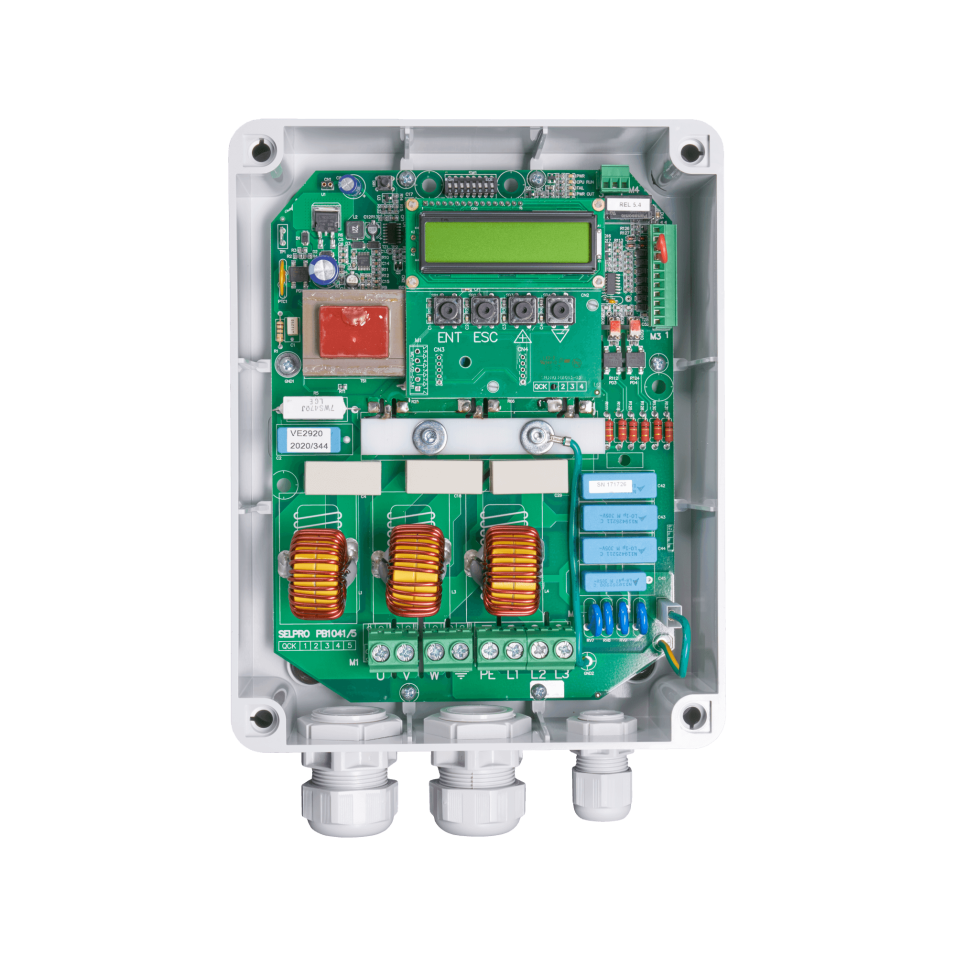

Grazie alla commutazione digitale sequenziale a 6+2 livelli, ogni variazione di tensione avviene in modo progressivo tramite autotrasformatori, con gestione soft-start su ogni gradino, riducendo picchi di corrente e sollecitazioni meccaniche ed elettriche sui motori dei ventilatori.

DSV è un regolatore elettronico avanzato, progettato per il controllo preciso, silenzioso ed efficiente, ideale per applicazioni HVAC/R quali drycooler, condensatori, chillere sistemi ventilanti con motori asincroni ad alto scorrimento.

Grazie alla commutazione sequenziale su 6+2 livelli di tensione sinusoidale, garantisce una regolazione a distorsione armonica nulla (THD 0%), evitando i problemi tipici dei sistemi a taglio di fase, senza generare ronzii e/o risonanza acustiche nei motori.

Il principio di regolazione si basa su autotrasformatori a gradini di tensione, gestiti da logica digitale con funzione soft-start su ogni gradino per eliminare picchi di corrente e stress meccanici. Il sistema seleziona automaticamente il livello di tensione più adatto in funzione del valore misurato, mantenendo la grandezza controllata entro la banda proporzionale al valore di setpoint desiderato.

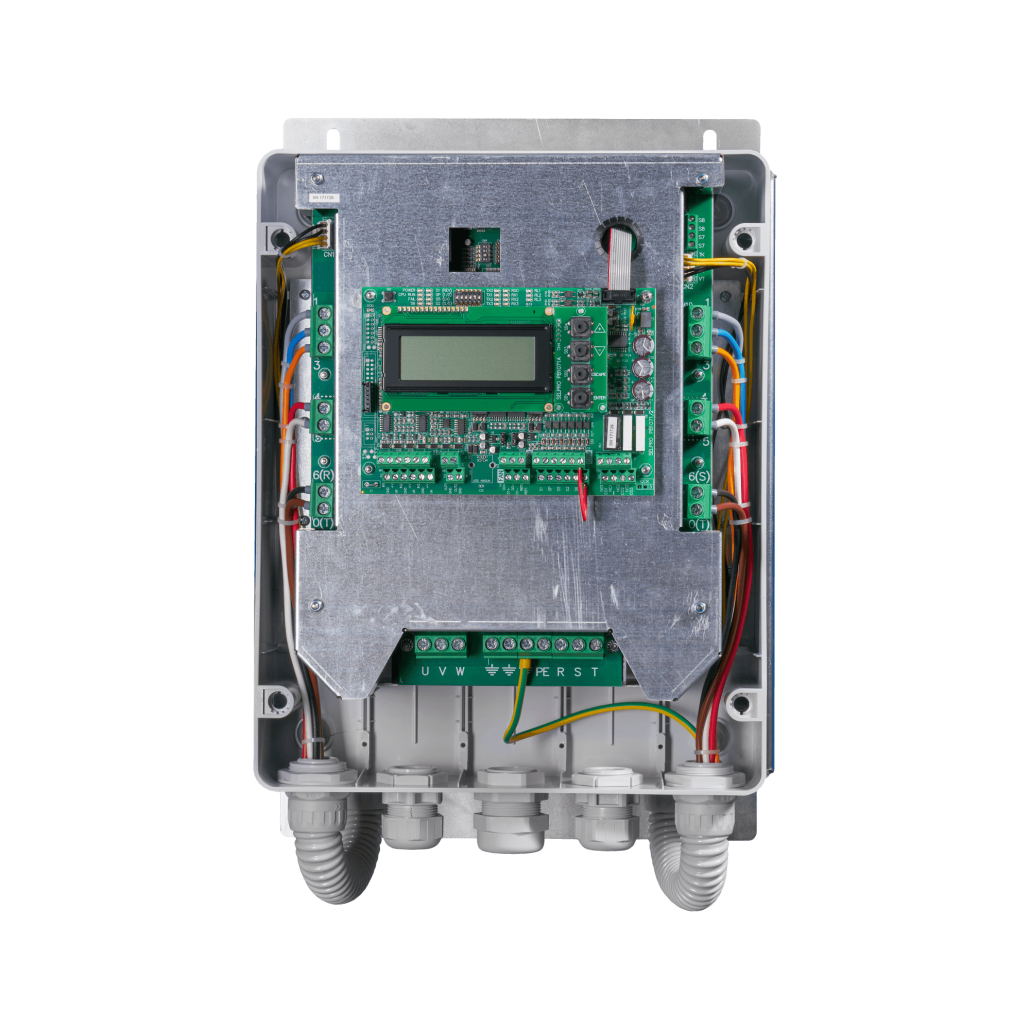

DSV è disponibile in versione Master o Slave proporzionale, e può alimentare gruppi di motori AC fino a 48A RMS nominali, con alimentazione trifase 400Vac. È compatibile con tutti i motori ad alto scorrimento, ed è dotato di contenitore IP55, protetto contro polveri, acqua e interferenze elettromagnetiche (EMC).

Flessibilità operativa e personalizzazione:

Supporta 2 setpoint indipendenti e 2 banchi di parametri personalizzabili, per la gestione di rampe di velocità, salti di tensione, limite notturno, modalità giorno/notte e logiche stagionali. La selezione del canale di regolazione può avvenire automaticamente in base alla grandezza più critica tra i 2 ingressi analogici disponibili.

Gestione intelligente dei sistemi adiabatici:

DSV è predisposto per il controllo evoluto dei sistemi adiabatici, con uscita proporzionale 0-10Vdc per pompe o inverter e comando On/Off tramite relè, attivabili in funzione della temperatura, di orari programmati o di soglie ambientali. La sinergia tra ventilazione e raffreddamento evaporativo assicura massima efficienza anche nelle condizioni più impegnative.

Diagnostica avanzata e affidabilità:

È dotato di registratore eventi con orologio interno (RTC) per la tracciabilità delle transizioni operative, degli allarmi e degli stati di regolazione. I parametri di funzionamento sono accessibili via interfaccia Modbus RTU, facilitando l’integrazione con sistemi BMS e la gestione remota del funzionamento. Le protezioni elettroniche contro sovratensioni, sovraccarichi, ventilatori bloccati e errori di alimentazione lo rendono ideale per impianti critici ad alta continuità di servizio.

DSV è la soluzione completa per la regolazione robusta, efficiente e intelligente dei motori trifase, per chi cerca silenziosità, affidabilità e connettività nei sistemi HVAC industriali.

Più silenzioso, più efficiente, più semplice

Ventilazione silenziosa e affidabilità 3 volte superiore. La soluzione più green e conforme per motori AC trifase: nessun filtro attivo o EMC richiesto, nessun rumore, nessun surriscaldamento, compatibilità totale, installazione plug & play e vita dei ventilatori triplicata.

Ingressi, uscite e connettività

- 3 ingressi analogici configurabili, compatibili con trasduttori 4-20mA, 0-10V, 0,5-4,5V e sonde NTC (-10°/+90°C), con selezione automatica del valore prevalente.

- Interfaccia Modbus RTU isolata, dedicata alla connessione con sistemi BMS o supervisori.

- 2 uscite 0-10Vdc programmabili, per dispositivi slave o per la gestione proporzionale del sistema adiabatico.

- 6 contatti ausiliari on/off programmabili, per funzioni operative quali Start/Stop remoto, cambio setpoint, limite notturno, modalità inversa, gestione TK e attivazione spray.

- 3 relè configurabili, per la gestione degli allarmi, dei warning e dei cicli del sistema adiabatico.

Caratteristiche speciali

- Tensione VAC in uscita perfettamente sinusoidale (THD = 0%), senza disturbi condotti o irradiati con Soft-start su ogni gradino e nessuno stress termico o elettrico al motore, la tecnologia Clean-power previene sovratensioni e picchi per una durata di vita fino a 3 volte superiore

- Funziona con motori AC trifase ad alto scorrimento , anche non a rotore esterno e l'Installazione può essere gestita da un solo operatore (fino a 48 A)

- Nessun filtro attivo per armoniche

- Nessun filtro sinusoidale per micro-onde

- Nessun filtro EMC

- Nessun cavo schermato

- Nessun surriscaldamento indotto nei motori

- Il dispositivo offre 2 setpoint di regolazione impostabili al limite minimo o al limite massimo e la possibilità di configurare 2 banchi di parametri personalizzabili, tra cui limite notturno, salti di velocità, velocità massima e minima, rampa di accelerazione e altri parametri operativi per una gestione flessibile e adattabile alle diverse esigenze.

2 output 0-10V indicati per asservire ad una unità principale (Master) una o più unità Slave, o per la gestione di un sistema adiabatico con un set di parametri dedicato.

- 0-10 Vdc

- Adiabatico

- Per l'accesso remoto ai parametri, tracciabilità eventi e una gestione avanzata tramite sistemi di supervisione esterni

- Registratore eventi per errori e warning del regolatore, errori dei ventilatori, cambio stato ingressi On/Off, stato uscite On/Off, registrazione temporizzata dello stato del regolatore